Hotline

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar

3000-6 IN 1 AUTOMATIC BOTTLE FILLING MACHINE VACGF3000

Contact

6-in-1 automatic bottle filling machine VACGF 3000 capacity of 3000 bottles / h

- Model: VACGF3000

- Capacity: 3000 bottles/h

- 1-year warranty

- Maintenance: Long-term

- Standard: ISO 9001:2015

- Free shipping-installation nationwide

Buy now

Free shipping

Request a consultation

Build your own plan

Order, advice 0949.41.41.41 - 0943.41.41.41 (7:30 - 21:00)

Category: FILLING-VACGF

Product code: VACGF3000

- Describe

- Parameters, configuration

- Picture

Product details

6-in-1 automatic bottle filling machine VACGF 3000- 6 automatic stages are integrated into one machine. This product line is improved technology higher than the 4-in-1 bottle filling machine VACGF2000 was born earlier.

Viet An is proud to be the best supplier of 6 in 1 automatic bottle filling machines in Vietnam

With this product will help improve productivity up to 3000 bottles per hour and ensure hygiene and safety. Let's find out about bottle filling machines VACGF3000 with 6 automatic stages through the following article.

6 in 1 automatic bottle filling machine - VACGF3000

Viet An General Trading Joint Stock Company is proud to be the leading company in Vietnam in the field of import, distribution and installation of automatic filling machines, including bottle filling machine VACGF3000- 6 in 1.

Formerly known as Viet An Trading Co., Ltd was equitized from August 2009, for nearly 20 years of construction and growth, with the constant efforts of the leadership and all employees in the company. We say no to fake and fake goods. Viet An has marketed genuine and high-quality products.

The results of these relentless efforts are the certificates and awards that the State and consumers have voted for Viet An.

Why should install 6-in-1 automatic bottle filling machine VACGF3000

Needs of the new era

In the era of industrialization and modernization, applying modern technology to production and business is an essential need of every business. Modern machines gradually replace workers to improve economic efficiency, increase productivity, ensure safety, lower product costs.

In the field of manufacturing bottled water is too. Need to apply machines to replace human labour. Especially, this industry has a very strict requirement of food safety and hygiene.

The international standard bottle filling machine

Designed with modern and compact industrial design. The whole material constitutes 6 in 1 bottle filling machine is high quality 304 stainless steel material, not rusty, easy to clean.

VACGF3000 with 6 most advanced automatic stages for the bottle filling process is much faster than other bottle filling machine on the market.

The whole process of manufacturing and assembling bottle filling machines have been ensured to meet the technical standards, supervised according to the most stringent international standards ISO 9001:2015 today. Model VACGF3000 has been registered by Viet An exclusively trademark of VA at Vietnam Intellectual Property Department No. 250969

Not only qualifying for use in Vietnam but also the VACGF3000 bottle filling machine with 6 automatic stages is eligible to export to ASEAN countries.

6 automatic steps required of VACGF3000

1: Air conveyors

Function:

- Automatically put the bottle in

- Gather the bottle together

With a capacity of up to 3000 bottles per hour, model VACGF3000 is equipped with an air conveyor system. This is a very important stage for the production process

Advantage:

- No need for regular maintenance and is easy to install

- Save space

- Can operate continuously.

- Eliminate leakage, contamination product when operating.

- Suitable for wet environments.

- Air conveyors help save labour, increase productivity.

- Contributing to creating a modern production environment

2 + 3 + 4: Automatic Rinse - filling-bottle filling – capping

Rinse:

Empty plastic bottles will be taken to 8 wash heads by gears conveyor. Empty bottles are rotated 180 degrees by clamps. Sequence 8 bottles of water will be kept by the spring clamping system and washed in and out with pure water. After being rinsed, the gear conveyor will be delivered to the bottle filling machine.

+ Filling:

Plastic bottles after being washed in and out will be conveyed by gear to the filling machine. In here, there are 8 filling heads installed on the principle of fixed liquid surface weight. The filling process takes place quickly, accurately, without leak. The filling system has a sensor attached so when the water level is reached, the program will stop. Ensure 99.9% accuracy. The rapid filling rate of 3000 bottles of 350ml, 500ml per hour and 800 to 1000 bottles of 1500ml per hour.

+ Automatic bottle capping:

The filled plastic bottles will be conveyed by the gear conveyor system to the bottle capping machine. It is designed with 3 capping heads to close the bottle cap. The bottle cap tightening force can be easily adjusted at the control panel to ensure that it is not damaged but secured tightly to the bottle.

5. Automatic bottle cap loading machine

As in the previous post, we have mentioned a phenomenon in the VACGF2000 bottle filling machine, it is the phenomenon the bottle cap is inverted by not using automatic bottle cap loading machine. VACGF2000 uses the cap container system and put the caps in manually, the cap rate is reversed to about 3%. Influences operating capacity and needs supervisors to operate.

With the 6-in-1 automatic bottle filling machine VACGF3000 can completely overcome the above limitation with this automatic bottle cap loading machine.

The bottle caps are poured into the tank lid of the loading machine. Conveyor motor system takes the bottle cap up to the position connected to the capping part. At the connection part attached the magic eye to count the number of bottle caps to move down and the air blowing system to blow the bottle cap into the duct.

A special feature of this automatic cap loading machine is to ensure 100% bottle caps in the right direction. Automatically insert the bottle cap when lack and stop the supply bottle cap when full cap at the duct with the capping unit

Stage 2: Automatic filling

After the bottle is cleaned with treated water will be transferred to the filling system, with 12 filling heads suitable for plastic bottles. On this system, there will be a speed-adjusting motor to help businesses become more proactive in production. On average, every hour, the machine will pour 2000 bottles of water.

The bottles after being washed will be transferred to the filling machine by the hold bottle mould system. In here, 12 automatic filling heads with a sensor system will pour the water into the bottle according to the installed capacity in the control panel. The filled bottles will be transferred to the bottle capping machine.

6. light inspection

Function:

- Detecting a strange object and in bottle

In pure water production, it always requires to ensure food hygiene and safety factor. So after the water bottles are filled, capping, labelled, they need to be taken to the light inspection machine

We can conduct an examination according to the probability when using this machine.

Platic conveyor

This is the part to connect, it helps move the bottle automatically, quickly without labour

Additional buying stages (optional)

Besides the 6 stages above, you can invest more:

1. Bottle loading and bottles arrange machine

Bottle loading and bottles arrange machine will save you a lot of costs. Because of the special design, this machine will automatically classify bottles, loading bottles to air conveyors to stack the bottles together, then transfer to the 3-in-1 filling and swirling washing machine without worker.

Specification of Bottle loading and bottles arrange machine

|

Model |

VALS4000 |

|

Machine capacity (BPH) |

2000-4000 |

|

Bottle type-2 mould (ml) |

300-1500 |

|

Electrical capacity (kw / h) |

0.75 |

|

Size (D * R * C mm) |

1200X1500X900 |

|

Weight / kg) |

150 |

|

Price (USD) |

5.900 |

2. Film shrinking machine

The heat shrink film machine uses the heat of the heat to shrink the film to the bottle, helping to protect the bottle against the impact of dirt, external mechanical force during transport.

Technical specifications of the Heat shrink film shrinking machine made in Vietnam

|

Model |

VAHS4000 |

|

Capacity (bottle / h) |

2000-4000 |

|

Electrical capacity (kw / h) |

18 |

|

Size (D * R * Cmm) |

"1800x500x1700" |

|

Weight / kg) |

48 |

| Price (USD) |

2.300 |

3. Inkjet printer

With the function of the expiry date in the form of spray. Beautiful, sharpen. Fast printing speed. Designed to print on PET plastic bottles

Help users to know the production date and expiry date of the product clearly.

Inkjet printer parameters

|

Model: |

VA22000 |

|

Maximum print line |

3 |

|

Electricity supply |

240V |

|

Size (D * R * C mm) |

400*320*527 |

|

Weight / kg) |

27 |

|

Price (USD) |

9.900 |

4. Semi-automatic bottle shrink wrapping machine

Characteristics: semi-automatic bottle shrink Log, high-capacity

With this machine will improve the capacity for the shrink-log process of 6, 12, and 24 bottles compared to manual shrink-log methods.

Membrane shrink into Log is beautiful, smoothy

Parameter of Machine semi-automatic bottle shrink Log

|

Model |

VAGS6000 |

|

Capacity (chai/h, log 24 chai 500ml ) |

4000-6000 |

|

Power (kW/h) |

18 |

|

Dimension (D*R*Cmm) |

4500*1000*2100 |

|

Price (USD) |

8.900 |

Differences of 6-in-1 automatic filling machine VACGF3000

Application of the most modern filling technology of the United States

Designed with 6 automatic stages, the most advanced according to the latest technology of the United States. VACGF3000 is manufactured and assembled in Viet An's factory or imported directly from the US, Italia, Taiwan, China. All production and assembly processes ensure quality standards.

Smart control panel

The whole process of washing, filling and capping ... being controlled by the PLC control system with the touch screen attached to the bottle filling machine. There is a "speed" button in here, you can easily increase or decrease the filling speed according to your preferences.

High capacity

With 6 automatic stages are integrated into a filling machine line. Operating capacity is equal to 10 employees. Therefore, when using VACGF3000 automatic bottle filling machine of Viet An, you will save a lot of labour rental costs while ensuring labour productivity. Ensure production safety. More specifically, creating a modern factory.

Filling many sizes of bottles

The creation of a variety of bottled water products to meet a wide range of uses is necessary. Previously when you used a conventional filling machine, you could only fill a certain type of bottle size. This makes production difficult and costly.

Now with VACGF3000 6 in 1 automatic bottle filling machine of Viet An, you will not have to worry about that problem anymore. This machine is designed to fill many types of bottles such as 350 ml bottles, 500ml bottles and 1500ml bottles.

When producing 350ml, 500ml bottles do not need to change anything. However, if you want to fill the bottle with a volume of 1500ml, you need to change the Mold set of each corresponding bottle.

The replacement time takes about 1 hour. So you can change production between shifts so it doesn't take time.

Investing in the installation of bottle filling machine VACGF3000 with 6 automatic stages

Currently creating a modern, automated production model becomes ever more necessary. Because of the strong competition of the market, the improvement of quality and cost reduction is always noticed by many business owners. You have a pure water factory, bottled water If you want to own an automatic bottle filling machine with these 6 stages, you can contact Viet An at 0942 414141

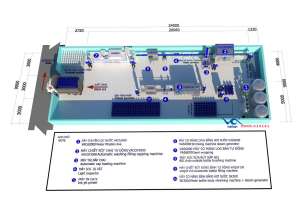

Premises for install bottle filling machine VACGF3000

With 6 automatic steps, if you want to install this VACGF3000 automatic bottle filling machine, you need to ensure that the area has a certain area. The following is Viet An's guide on the installation site you need to prepare

Image of installation ground

In addition to automatic bottle filling machine with 6 stages VACGF3000, Viet An also provides many other types of machines such as bottle blowing machine, water filter line for customers to choose.

See more article details

Specifications of automatic filling machine VACGF3000

|

A. VACGF3000 FILLING MACHINE - 6 STAGES MUST BE BUYED |

|

|

Model |

VACGF3000 |

|

Wash head |

8 |

|

Extraction head |

8 |

|

Head swirled |

3 |

|

Machine capacity (350ml bottle / h) |

2500 - 3000 |

|

Machine capacity (500ml bottle / h) |

2500 - 3000 |

|

Machine capacity (1500ml bottle / h) |

700-1000 |

|

Power capacity |

2.24 |

|

Pressure |

0.6-0.8MPA |

|

Bottle size |

Φ55-Φ100 |

|

Bottle height |

100-320 |

|

Electricity supply |

380v-50hz |

|

3 in 1 size |

2100*1500*2200 |

|

Weight |

1500 |

|

Air conveyor |

2000*220*1000 |

|

Bottle cap loading (D*R*Cmm) |

1200*950*3000 |

|

light inspection |

600*200*1000 |

|

Plastic conveyor |

10000*160 |

|

Price ( USD) |

|

|

B. SEPARATE PURCHASE STAGE INTEGRATED INTO A 6 IN 1 FILLING MACHINE - VACGF3000

|

|

|

Model |

Price ( USD) |

|

1. Bottle loading and arranging machine - VALS4000 |

|

|

2. Heat shrink film machine - VAHS4000 |

|

|

3. Inkjet printer - VA22000 |

|

|

4. Semi-automatic log shrinking machine-VAGS6000 |

|

Hỏi đáp & đánh giá 3000-6 IN 1 AUTOMATIC BOTTLE FILLING MACHINE VACGF3000

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi