Hotline

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar

24000-6 IN 1 AUTOMATIC BOTTLE FILLING MACHINE-VACGF24000

Contact

6-in-1 automatic bottle filling machine VACGF 24000 capacity of 24000 bottles / h

- Model: VACGF24000

- Capacity: 24000 bottles/h

- 6 automatic stages

- 1-year warranty

- Maintenance: Long-term

- Standard: ISO 9001:2015

- Free shipping-installation nationwide

Buy now

Free shipping

Request a consultation

Build your own plan

Order, advice 0949.41.41.41 - 0943.41.41.41 (7:30 - 21:00)

Category: FILLING-VACGF

Product code: VACGF24000

- Describe

- Parameters, configuration

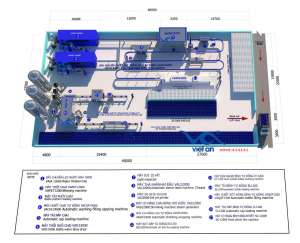

- Picture

Product details

6 in 1 automatic bottle filling machine VACGF24000 is familiar equipment in the production line of bottled and jar drinking water.

With the process of transport, washing, filling, swirling cap, bottle cap loading and automatic stranger object detection, high capacity. This is the optimal choice for manufacturers.

With modern, compact industrial design. Products are supplied and installed by Viet An Company

As more and more people choose to use bottled drinking water to use. Open up great opportunities for businesses to invest and expand production and business.

To increase productivity, it is not possible to use semi-automatic filling machines. Because of the capacity limitation, besides the semi-automatic machine, so many workers are involved, the hiring costs are constantly increasing, costing, increasing the cost of goods and low profits.

With the advancement of science and technology, the automation trend has been adopted by many industries, including the bottled beverage industry.

Currently, with modern technology, many industrial processes are automated. In which automatic bottle filling and capping line are one of the most widely used and widely used systems.

VACGF24000 6-in-1 Automatic Bottle Filling Machine with multiple automatic stages to create a closed, automatic high-power process. With VACGF24000 model, only a few workers need to participate in production activities but high labour productivity and hygiene safety.

6-in-1 automatic bottle filling machine VACGF24000 latest technology 2021

Model VACGF24000 is the advanced 6 in 1 automatic bottle filling machine in Viet An. Applying the modern technology of automatic washing, filling and screwing cap of the US in 2021.

Viet An is the company in Vietnam and the 4th in Southeast Asia in the field of supplying various kinds of high capacity automatic bottle filling and jar filling machines. With nearly 20 years of construction and growth, we always focus on product quality and service quality improvement. Viet An has gradually affirmed its position in the country as well as its 4th position in the Southeast Asia market. With great achievements voted by the state, business partners and consumers.

Besides providing genuine automatic filling machines, Viet An also launched the pure water filters, electrolyte water purifiers, mineral water purifiers and industrial ice cubes making machine with high durability, ISO 9001:2015 quality standard.

The machine consists of 6 stages connected to each other by a conveyor system uniformly. Create an automated, self-contained production process.

The operation process is simple, easy to adjust changes in operating capacity. Operation parameters are fully displayed on the LCD touch screen of the Control Panel.

The machine operates stably, saving electricity, saving fuel, high durability.

6-in-1 automatic bottle filling machine VACGF24000 is the first choice for today's bottled water manufacturer

We are living in a digital age when machines are gradually replacing people in all production and business activities. Therefore, if bottled water plants do not improve their technology, invest in technology, and use automated machines for production, it will be difficult to compete with other competitors.

With 6 automatic steps: Automatically put the bottle automatically without distance quickly with the AC-2 air conveyor. Automatically wash bottles with a system of 50 wash heads. Automatically filling water into bottles with 50 filling heads. Automatically screw cap into the bottle with 15 screw cap head. Automatically load the bottle cap quickly, without flipping the cap. Automatically detect strange objects in the finished bottle. Each hour the model VACGF24000 operates with the capacity of 20 workers. Therefore, when installing this 6-in-1 automatic bottle filling line, Viet An will only save about 140 million VND per month for labour costs.

Benefits of the 6 in 1automatic bottle filling machine VACGF24000

Labour saving:

With a factory producing pure bottled water, non-carbonated soft drinks when using 6-in-1 automatic bottle filling machines, the labour productivity can be up to 24,000 bottles per hour with only a few employees. Capacity increases by 200-400% compared to using normal labour.

Saving electricity costs, saving time:

With the model VACGF24000 designed with 6 automatic stages, operating according to the predetermined process, the shortest time, no downtime. The machine is designed to operate automatically 24/7 and minimize the incident.

High precision:

The production parameters of bottled water on the VACGF24000 6 in 1 automatic bottle filling line are shown on the touch panel of the control panel, strictly controlled, accurate according to the predetermined programming. Therefore, the process of producing bottled water is highly effective with almost absolute accuracy.

Reduce product prices:

Due to automatic production, high productivity up to 24000 bottles of 500ml per hour without much labor, enterprises can create water bottles with the lowest price. Meanwhile, the cost of producing a bottle of water compared to semi-automatic models is reduced by 50-60%. This makes it possible for businesses to lower costs to increase competitiveness while still ensuring profits for businesses

Meet the requirements of food hygiene and safety:

Today to ensure the health of the community, the regulations on water production, bottled water business to ensure food safety and hygiene are always strengthened by the central management and monitoring measures. While small-capacity semi-automatic filling machine, which requires a lot of workers, make cleaning difficult. Then the automatic filling lines will be an effective solution, meeting the most rigorous requirements, ensuring safety and hygiene because of its closed and automated production process.

6 automatic stages of automatic bottle filling machine VACGF24000

Stage1: Air conveyors AC2

It is an indispensable part of large capacity filling lines.

Function:

- Insert the bottle automatically from the automatic bottle blowing machine system or the bottle container into the bottle washing unit.

- Gather the bottle together

Uses:

The use of air conveyors helps to save labour, limit the number of workers, reduce time and increase labour productivity. The cylinder head system in the washing machine is designed with equal spacing. If the plastic bottles are transported in there is a distance that will cause the bottle-neck clip to operate incorrectly. May damage the bottle-neck and stop working. Affecting labour productivity. Therefore, we can see the important role of this air conveyor.

Stage 2 + 3 + 4: Rinse wash-filling- 3 in 1 bottle capping

+ Rinse the bottle automatically

Model VACGF24000 is equipped with up to 50 washing heads much higher than the previous 6 in 1 automatic washing machines.

Function:

- Automatic bottle washing

- Contributing to ensuring food safety and hygiene

Uses:

Due to 50 wash heads, use compressed air pressure into the duct system. When the bottle is transported to the washing device by the gears. Here 50 bottleneck clamps will clamp the bottleneck and turn the bottle 180 degrees, upside-down bottle to catch on the washing heads. Water from 50 heads washed under high pressure will spray up into the bottle to wash away the dirt in the bottle at a high speed of up to 24,000 bottles per hour.

+ Automatic bottle filling

VACGF24000 is equipped with up to 50 filling heads. All are imported from Italy with the best quality today. There is a sensor attached to the bottle filling machine to automatically quantify the water into the bottle according to the preset.

Function:

- Automatically fill water into the bottle according to norms and accuracy

- Self-disconnected when no bottle

This helps the water production process to save materials with maximum filling speed, absolute precision

+ Close the bottle automatically

The machine is equipped with up to 15 screw heads. The screw cap is made of steel and plated with a high quality 304 stainless steel layer with a shiny surface. The inside of the screw heads is fitted with marbles to ensure the impact force, so the cap is adequate.

Function:

- Close the cap to the bottle automatically

Each machine can close 24,000 bottle caps every hour

Stage 5: bottle cap loading machine

This is an extremely important part of the filling machine.

Function:

- Automatically put the bottle cap on the cap screw unit

- Keeping the bottle cap in the right direction is not reversed

With the capacity of filling and screwing cap up to 24,000 bottles per hour, it is impossible to lack this bottle cap loading machine. It is composed of 1 tray containing cap by stainless steel. With a capacity of 2 thousand caps. So just pour caps one time into the container for 1 shift work. The cap tray is attached with a cap conveyor which is kept by 304 stainless steel frame. When the pump operates, the bottle caps are loaded on the conveyor. At the top of the conveyor, the connection to the duct system will be connected to the cap screwing machine. Before the cap is brought to the duct, the cap will have a compressed air blowing system to blow the bottle cap into the pipe in the right direction. As such, the bottle cap will be loaded up by the conveyor and the air blower will blow to the duct. At the contact head between the duct and the cap conveyor, one magic eye is attached to count the number of bottle caps passing. At the under the head of the cap duct where attached cap screw head, there is also a magic eye to count the number of caps.

Stage 6. light inspection

Function:

- Detecting strange objects in bottles

- Ensuring hygiene safety for production

The light inspection will be placed parallel to the conveyor system transport the finished water bottles. Here, due to being attached to the induction magic eye penetrating can look through the water bottles, strange objects can be identified in the bottle and alerted to the workers to remove the bottle.

Automatic stages purchase separately (Optional)

In addition to the 6 automatic steps required above of the 6 in 1 automatic bottle filling machine VACGF24000, you can invest in the purchase of some other automatic steps below to produce the bottled water automatically.

- Bottle loading and bottles arrange machine VALP22000

- Bottle dry blow machine -VAD22000

- 2-head label drop machine -VAL22000

- Automatic rotary labelling machine to label the round bottle with opp label and hot melt glue-VAR2200

- Steam bottle shrinking machine VAS22000

- Inkjet printer-VA22000

- Automatic log shrinkage machine-VAGM20000

See more article details

Specifications of automatic filling machine VACGF24000

A. VACGF24000 FILLING MACHINE - 6 STAGES MUST BE BUYED

|

Model |

VACGF24000 |

|

Wash head |

50 |

|

Extraction head |

50 |

|

Head swirled |

15 |

|

Machine capacity (350ml bottle / h) |

20000-24000 |

|

Machine capacity (500ml bottle / h) |

20000-24000 |

|

Machine capacity (1500ml bottle / h) |

6000-7000 |

|

Power capacity |

9.5 |

|

Pressure |

0.6-0.8MPA |

|

Bottle size |

Φ55-Φ100 |

|

Bottle height |

100-320 |

|

Electricity supply |

380v-50hz |

|

3 in 1 size |

5300*3200*2850 |

|

Weight |

9000 |

|

Air conveyor |

12000*220*1000 |

|

Bottle cap loading (D*R*Cmm) |

1200*950*3000 |

|

light inspection |

600*200*1000 |

|

Plastic conveyor |

75000*160 |

|

Price (USD) |

|

B. SEPARATE PURCHASE STAGE INTEGRATED INTO A 6 IN 1 FILLING MACHINE – VACGF24000

|

Model |

Price (USD) |

|

1. Bottle loading and arranging machine – VALP22000 |

|

|

2. Bottle blowing machine – VAD22000 |

|

|

3. Double-headed label drop machine – VAL22000 |

|

|

4. Automatic rotary labelling machine for labelling round bottles with opp labels and hot melt glue stick – VAR22000 |

Contact |

|

5. Steam bottle shrink machine – VAS22000 |

|

|

6. Inkjet printer - VA22000 |

|

|

7. Semi-automatic log shrinking machine-VAGM24000 |

|

Hỏi đáp & đánh giá 24000-6 IN 1 AUTOMATIC BOTTLE FILLING MACHINE-VACGF24000

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi