Hotline

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar

VAQGF150 3 in 1 Automatic Bottle Filling Machine

Contact

3 in 1 Automatic bottle filling machine VAQGF150

- Capacity: 150 bottles of 20 liters/hour

- Origin: Genuine

- Warranty 12 months

- Free shipping-installation nationwide

Buy now

Free shipping

Request a consultation

Build your own plan

Order, advice 0949.41.41.41 - 0943.41.41.41 (7:30 - 21:00)

Category: FILLING-VAQGF

Product code: VAQGF150

- Describe

- Parameters, configuration

- Picture

Product details

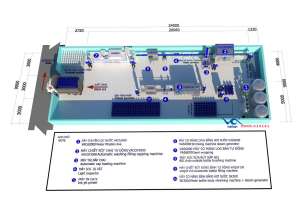

VAQGF 150 3 in 1 automatic bottle filling machine of Viet An special quantitative filling with absolute precision, this product has satisfied a lot of customers in the bottled beverage business. , close the bottle. With the design of automatic running, this filling machine is much more productive than conventional filling machines.

VAQGF 150 3-in-1 automatic bottle filling machine is the latest technology bottle filling machine imported and distributed by Viet An Joint Stock Company in Vietnam. Machines manufactured with the modern technology of the United States are assembled in Shanghai-China according to ISO 9001:2015.

Uses of 3 in 1 automatic filling machine VAQGF 150

VAQGF 150 automatic 3-in-1 bottle filling machine is used to pour water into a 20L jar with a capacity of 150 bottles / h.

The device is designed to intelligently protect when there is no bottle, the machine stops working without filling, helping to handle situations of empty bottles or problems of stuck. In such situations, the system automatically prevents the pumping system from discharging the material, minimizing the source of water loss.

VAQGF 150 automatic 3-in-1 bottle filling machine automatically cleans, extracts and closes in a closed cycle, greatly reducing labour in the production process, achieving efficiency and high quality.

The machines in the line are highly automated, people only participate and operate, providing the best productivity for users and the safety measures of power all systems are designed against shock and other electrical equipment up to standard. Emergency shutdown button when something goes wrong.

The stages of the automatic filling machine 3 in 1 VAQGF 150

VAQGF 150 includes 3 main stages:

- Automatic rinsing: The bottle that has been withdrawn will be transferred to the conveyor moving along the conveyor to the automatic pressure jar coating unit, where the bottle will be fixed on the coated tray by the bottle holder. Combined with the Conveyor Motor help rotates in a fixed direction to speed up the rinsing process. 304 stainless steel head pump, pure water pump and sterilized ozone will use the high-pressure pump inside the jar cover to make all bacteria in the jar destroyed to ensure the bottle is 100% clean.

- Filling bottle: 1 tap of filling with 304 stainless steel has the effect of filling water bottles according to the pre-installed level on the control panel. Pressure spring system carries water to the filling tap. Combined with the 304 stainless steel head pumping system creates a potentiometer, creating pressure to filling the water.

- Automatic bottle capping: VAQGF 150 has a bottle cap stamping unit for small neckless bottles without thread, combined with a 304 stainless steel conveyor assembly with a roller system. There is a cap roll into the capping unit and a hydraulic cylinder to push the water out.

Automatic purchase stage separately (optional)

VAQGF150 bottle filling machine capacity of 150 is extremely intelligent design. Besides the 3 automatic stages of the machine, you can expand up to 12 automatic stages to minimize labour costs and can improve productivity in the most optimal way.

Here are some automatic steps you can integrate into the VAQGF150 filling

1. BS-1 Decapping inside and outside bottle brushing machine

With modern technology design, compact, BS-1 decapping inside and outside bottle brushing machine will help you to remove the lid from the bottle cover after collect. Wash soil, dirt and dust from the outside and in the jar before reusing them.

+ Bottle washing machine, BS-1 bottle cap extractor is composed of: panel system, 1 cap retractor head, 1 pedal switch, inside and outside washing chamber.

The operating mechanism of BS-1 machine

- The device is connected to a power source

- Workers put 20-litre bottles in place to withdraw cap

- Step on the pedal switch. Under the effect of the cap withdrawal cylinder, the lid will be removed from the jar intact, not deformed, and go into the container lid to reuse.

- The 20l jar after being removed will be put into the washing chamber. Here the water pump system starts to work, water will be put into the machine at the same time the brush system works clockwise. Under the action of a brush, the 20l jar also moves in a clockwise direction. External brush, bottom brush, inside the bottle, the shell will be cleaned inside and outside clean.

You can use the water source of RO membrane or tap water to clean the inside and outside the jar.

|

Model |

BS1 |

|

Capacity (jar / h) |

150-200 |

|

Wash head |

1 |

|

Electricity supply |

1.1kw |

|

Pressure (Mpa) |

0.45-0.6 |

|

Dimensions (LxWxH) |

770x800x1150 |

|

Weight / kg) |

40 |

|

Price (USD) |

|

2. Light inspection (DJ-100)

The device is designed for the purpose of detecting strangle object in bottles according to probability. With the structure of the light system, the lamp holder.

With the cost of only a few million VND, Viet An advised that if you want to ensure the quality of bottled water produced by your unit, you should invest in this DJ-100 light inspection.

- Shrinking machine steam generator (SK-300)

The steam bottle shrink machine consists of a boiler and a shrink chamber.

Advantages: film shrinkage jar speed is fast, evenly, the film does not wrinkle, easily adjust the jar shrinkage capacity. The chamber is made of high quality 304 stainless steel, the bottom of the chamber has water collection pit.

Operation of the machine is easy.

First: 20l water bottles after being filled and closed capping then the worker will be catchup membrance into bottle body.

Then the 20l jar was conveyed by the conveyor system through steam film shrinking machine. Inside the shrink chamber is designed with small vents, the amount of heat from the boiler will be put into the shrinking chamber through the pressure regulating valve system to heat the membrane to adhere to the jar body.

Specifications of Shrinking machine steam generator (SK-300)

|

Model |

SK-300 |

|

Capacity (jar / h) |

100-300 |

|

Power(kw) |

18 |

|

Size (DxRxCmm) |

1500x550x800 |

|

Price (USD) |

|

- heat bottle shrinking machine (SK-300E)

It is a type of machine used to shrink 20-liter membrane bottles using heat. With intelligent design, the machine has an automatic temperature control system. To ensure a fixed temperature level within the shrinking chamber. The machine is durable, fast shrinking speed

Technical specifications of heat bottle shrinking machine

|

Model |

SK-300E |

|

Capacity (jar / h) |

100-300 |

|

Power(kw) |

18 |

|

Size (DxRxCmm) |

|

|

Price (USD) |

|

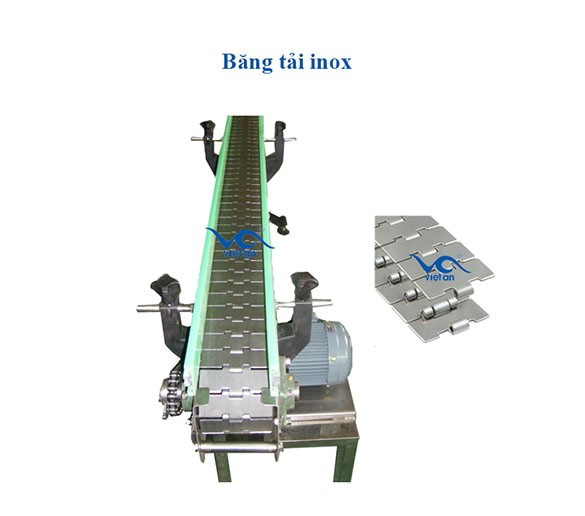

- Stainless steel conveyor for water jar containing CSSG-4

Uses: 304 stainless steel conveyor is used to move the 20-litre jar after it is filled with water automatically

Benefits: Save space, save labor, durable. Moving the water bottle is fast, high productivity

Technical specifications of Stainless steel conveyor

|

Capacity (jar / h) |

CSSG-4 |

|

Power(kw) |

0.75 |

|

Size (DxRxCmm) |

4000x290 |

|

Price (USD) |

|

Specifications of 3 in 1 automatic bottle filling machine VAQGF 150

Model: VAQGF 150

The capacity of the machine is from 120-150 bottles per hour.

The operating pressure of the machine on the whole process reaches 0.45-0.6Mpa with this pressure the stages of washing, filling or capping are guaranteed with absolute accuracy.

Machine size DxRxC: 2800x980x1700 (mm) with this size the automatic 3-in-1 automatic filling machine VAQGF 150 does not take too much area, designed with inox 304 always shiny machine easy to clean and clean as Lifespan is durable over 15 years

The machine is intelligently designed to save power up to an electrical capacity of only 1.92Kw / h

VAQGF 150 automatic 3-in-1 bottle filling machine is applicable for jar has to size 276x490

In order for the device to operate at its best, customers also need to prepare a 3-phase power source, the input power is 380V.

Weight of VA 3F automatic 3-in-1 bottle filling machine reaches 225 Kg with this easy weight for transport and installation.

Benefits of using 3-in-1 automatic bottle filling machine VAQGF 150 of Viet An!

- The machine is manufactured using the most modern filling technology of the United States

- Compact design machine, 304 stainless steel material is durable, easy to operate

- There is an intelligent control panel that automatically switches off when has a problem.

- There is a fully automatic PLC control system imported from Korea, Japan

- Filling process ensures food safety and hygiene for bottled drinking water

- With 3 automatic stages, VAQGF 150 will help businesses save the cost of hiring 2 workers after 1 year can payback the capital.

- Long-term warranty of up to 12 months and almost lifetime maintenance of the machine

Price of 3 in 1 automatic bottle filling machine VAQGF 150 in Viet An

With 3-in-1 automatic filling and filling machine VAQGF 150 with 3 automatic stages of washing, pouring, filling and capping at 129,000,000 VND, this price includes transportation and installation in 64 provinces and cities all over the country (except for islands).

Besides, when buying a machine in Viet An, customers will be consulted on the instructions on the filling machine in detail, any questions will be answered quickly and accurately by us. Customers who buy the VAQGF 150 bottle filling machine will get a 1-year product warranty with long-term maintenance along with many attractive gifts and after-sales regime.

We will advise and design the ground, advice on the filling machine production process as well as legal documents to help save costs for customers.

In addition, we also support you to design and print bottle labels, support jars with suppliers of plastic bottles, shrink film ... as well as consulting and sharing business strategies.

We are committed to providing our customers with the highest quality and most prestigious products, all the machines we provide are certified and tested by the competent authorities. Hope that Viet An is cooperating with customers in the shortest time. Hotline: 0942 41 41 41

Viet An supply addressing automatic filling machine 3 in 1 VAQGF - 150 PRESTIGE - QUALITY - CHEAP PRICE nationwide.

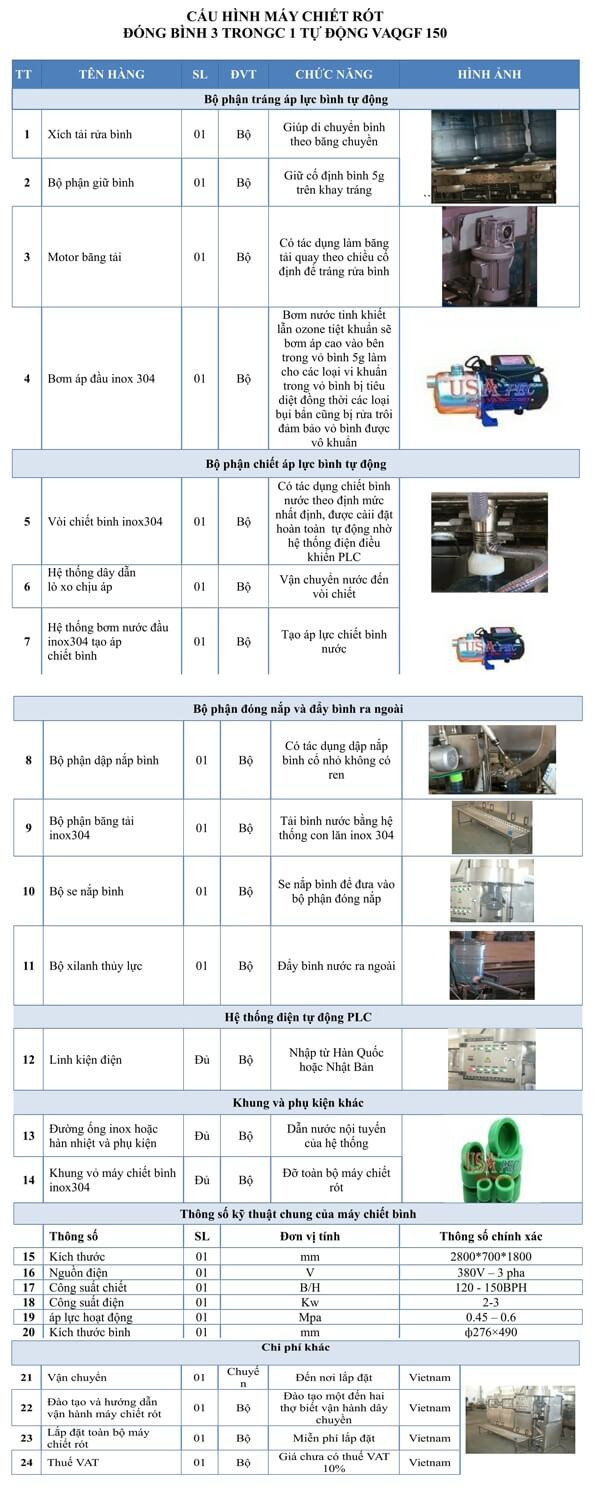

Detailed configuration of VAQGF 150 bottle filling machine

See more article details

Specifications of 3 in 1 Automatic jar filling machine VAQGF150 (Must be buyed)

A. 20l JAR FILLING MACHINE VAQGF150 – 3 STAGES MUST BE BUYED

|

Model |

VAQGF150 |

|

Extraction head |

120-150 |

|

Head swirled |

1 |

|

Power capacity (kw/h) |

1.9 |

|

Pressure (Mpa) |

0.45-0.6 |

|

size (D*R*Cmm) |

2800x980x1700 |

|

Weight (Kg) |

225 |

|

Price (USD) |

|

B. SEPARATE PURCHASE STAGE INTEGRATED INTO A 3 IN 1 JAR FILLING MACHINE VAQGF150

|

Model |

Giá( VNĐ) |

|

1. BS-1 Decapping inside and outside bottle brushing machine |

|

|

2. DJ-100 light inspection |

|

|

3. SK-300 Shrinking machine steam generator |

|

|

4. SK-300E heat bottle shrinking machine |

|

|

5. CSSG-4 Stainless steel conveyor for water tank containing |

|

Hỏi đáp & đánh giá VAQGF150 3 in 1 Automatic Bottle Filling Machine

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi