Hotline

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar

VAQGF100 3 in 1 Automatic Bottle Filling Machine

Contact

3 in 1 Automatic bottle filling machine VAQGF100

- Capacity: 100 bottles of 20 litres/hour

- Origin: Genuine

- Warranty 12 months

- Free shipping-installation nationwide

Buy now

Free shipping

Request a consultation

Build your own plan

Order, advice 0949.41.41.41 - 0943.41.41.41 (7:30 - 21:00)

Category: FILLING-VAQGF

Product code: VAQGF100

- Describe

- Parameters, configuration

- Picture

Product details

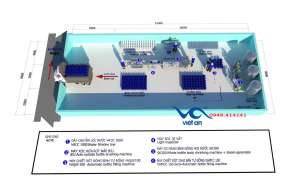

3-in-1 automatic bottle filling machine VAQGF 100 guarantees the best quality reputation.

The machine is imported, distributed, manufactured and installed by Viet An General Trading Joint Stock Company.

The pure drinking water market is growing day by day with increasing demands from consumers. Water pollution, environmental pollution is an extremely difficult problem, many people want to find pure water to ensure the health of coal and their families when the quality of well water or tap water have been boiled but still not guaranteed to be 100% clean of impurities. The solution of pure water produced by units is indispensable for consumers.

Viet An General Trading Joint Stock Company with 20 years of experience in the field of water purification and filling machine technology has provided the VAQGF 100 jar filling machine with a new solution for pure water production enterprises. with automatic filling system 3 in 1 maximum energy savings for businesses

Introduction of 3-in-1 automatic bottle filling machine VAQGF 100

VAQGF 100 3-in-1 automatic bottle filling machine, supplied by Viet An General Trading Joint Stock Company, is one of the specialized equipment used for automatic bottling of pure water. The product is manufactured using the most modern filling technology of the United States. With 3 stages of automatic scouring, filling and unscrewing the cap automatically (no thread type). With these three stages, businesses will save a lot of production costs, but productivity increases many times compared to conventional types of filling machine.

The number 100 corresponds to a capacity of 100 bottles of 20 litres/ hour. The machine is manufactured and assembled in the USA, Taiwan, and Shanghai according to ISO 9001:2015. VAQGF 100 bottle filling machine is imported and distributed by Viet An General Trading Joint Stock Company nationwide.

The main stage of 3 in 1 VAQGF automatic bottle filling machine

We would like to offer the automatic stages of automatic bottling filling machine 3 in 1 VAQGF 100 for your business very clear operation process of the machine. VAQGF 100 includes 3 automatic stages: washing the filling bottle and closing the bottle.

Bottle washing step:

- Bottle washing chain conveyor

- Bottle holder

- Motor conveyor

- 304 stainless steel pressure pump

The bottles that have been withdrawn will be sent to the holder during the automatic rinsing process of the VAQGF100 bottle filling machine. The jar shell will be fixed and moved by the conveyor chain under the action of the conveyor motor.

Washing stage is equipped with a 304 stainless steel head to pump genuine imported from Italy. This pump is used to pump both pure water and sterilized ozone into the 5G tank shell to clean the inside of the jar before sending it to the filling unit.

Bottle filling process: The 3 in 1 automatic bottle filling machine VAQGF 100 has 1 tap with iNox 304, which can fill the bottle according to a certain norm already installed on the control panel. Pressure spring system carries water to the filling tap. Combined with the 304 stainless steel head pumping system creates a potentiometer, creating pressure to fill the water.

The process of closing the bottle cap: Pressing the bottle for small neck type without threaded, combined with the conveyor part made of 304 stainless steel loading the jar with a roller system. There is a vehicle with a lid to put in the lid and a hydraulic cylinder to push the water out.

Above are the main stages of the 3-in-1 automatic bottling filling machine VAQGF 100, besides to increase productivity we also provide auxiliary machines to help the filling process take place than effectively.

Stage auxiliary purchased separately (not mandatory)

1. BS-1 semi-automatic Decapping inside and outside bottle brushing machine

This is a machine that works to remove the cap from the jar when the manufacturer collects the bottle of the dealer or the user.

The collected shells have covered with dirt and have a lid. So before you put into use, you should invest in installing a cap dispenser, this BS1 semi-automatic decapping inside and outside bottle brushing machine.

With the design of a cap retractor, the inside has a brush system for inside and outside sweeping, a sprinkler system for washing the cover, a pump system, a pressure pedal to remove the lid.

The water to wash the flask in this BS1 is the sewage system of the RO filter. Or tap water treated well water.

Workers will put the cover in the position to remove the lid. Then click on the pedal to remove the cover. The cap will be removed from the jar and drained out for reuse.

Specifications of semi-automatic Decapping inside and outside bottle brushing machine

|

Model |

BS1 |

|

Capacity (average / h) |

150-200 |

|

Wash head |

1 |

|

Electricity supply |

1.1kw |

|

Pressure (Mpa) |

0.45-0.6 |

|

Dimensions (LxWxH) |

770x800x1150 |

|

Weight / kg) |

40 |

|

Price (USD) |

|

2. light inspection

The light inspection is placed next to the conveyor belt system right behind the 3 in 1 bottle filling machine.

The machine helps to check the probability of the jars during production. With the structure of a lamp, help you see through the inside of the jar to see if there are any strangle objects. If the bottle does not meet the standard, discard it. The cost of investing in this light inspection is very cheap, so I think everyone will invest to buy the machine to scan the object in this 20-litre bottles.

Technical specifications of light inspection

|

Model |

DJ-100 |

|

Power( W) |

3x20w |

|

Size (DxRxCmm) |

600x200x1000 |

|

Price (USD) |

|

3. Shrinking machine steam generator

In order not to waste labour for the membrane shrinkage stage, the purchase of a shrinkage machine is very reasonable because the machine will operate quickly with a capacity of 100-300 bottles / h, a lot faster than made by manual method.

Technical specifications of the Shrinking machine steam generator

|

Model |

SK-300 |

|

Capacity (jar / h) |

100-300 |

|

Power(kw) |

18 |

|

Size (DxRxCmm) |

1500x550x800 |

|

Price (USD) |

|

When ordering filling products at Viet An customers will have a warranty of 1 to 2 years and maintained indefinitely.

- heat bottle shrinking machine

Based on the heat of the heat to shrink the membrane into the whole jar body, SK-300E will help businesses improve the quality of their own water bottles. The machine has the ability to adjust the temperature itself, so it is absolutely safe to have shrink films. Membrane shrinks the whole body to ensure beautiful, not wrinkled.

Technical specifications of heat bottle shrinking machine

|

Model |

SK-300E |

|

Capacity (jar / h) |

100-300 |

|

Power(kW) |

18 |

|

Size (DxRxCmm) |

|

|

Price (USD) |

|

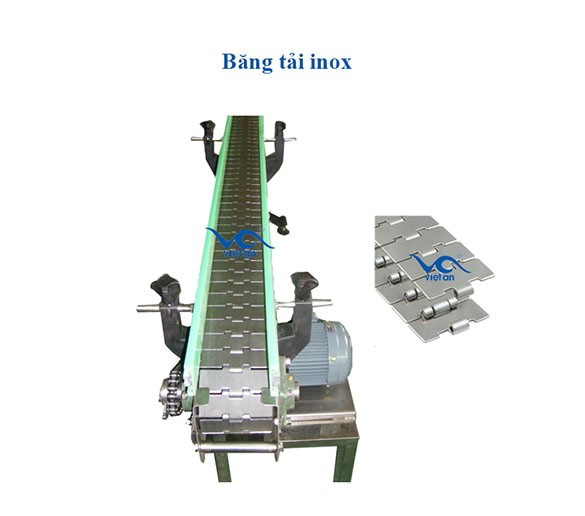

- Stainless steel conveyor for water tank containing

Uses: automatic water dispenser without labour

Designed with high quality 304 stainless steel with high durability. Inox conveyors include conveyor systems, and pump systems, conveyor frames

With the use of stainless steel conveyor will help manufacturers save a lot of labour costs, save production space.

Technical specifications of Stainless steel conveyor

|

Capacity (jar / h) |

CSSG-4 |

|

Power (kW) |

0.75 |

|

Size (DxRxCmm) |

4000x290 |

|

Price (USD) |

|

Above are all the main stages as well as auxiliary machines for the filling process of the 3-in-1 automatic bottle filling machine VAQGF 100. Customers want to purchase the machine please contact the Viet An company hotline: 0942 41 41 41 for free advice and support.

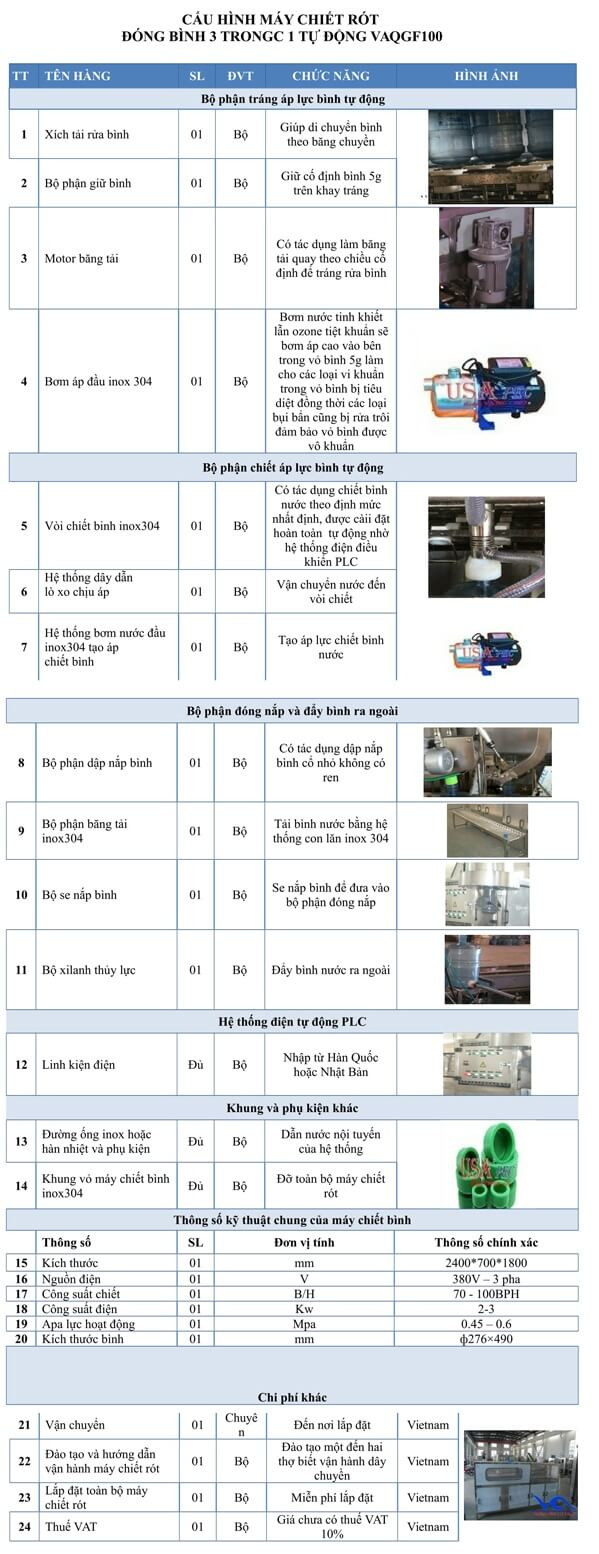

Detailed configuration of VAQGF 100 bottle filling machine

See more article details

Specifications of 3 in 1 Automatic jar filling machine VAQGF100 (Must be buyed)

- 20l JAR FILLING MACHINE VAQGF100 – 3 STAGES MUST BE BUYED

|

Model |

VAQGF100 |

|

Extraction head |

70-100 |

|

Head swirled |

1 |

|

Power capacity (kw/h) |

1.55 |

|

Pressure (Mpa) |

0.45-0.6 |

|

size (D*R*Cmm) |

2730x660x1720 |

|

Weight (Kg) |

180 |

|

Price (USD) |

|

- SEPARATE PURCHASE STAGE INTEGRATED INTO A 3 IN 1 JAR FILLING MACHINE VAQGF100

|

Model |

Giá( VNĐ) |

|

1. BS-1 Decapping inside and outside bottle brushing machine |

|

|

2. DJ-100 light inspection |

|

|

3. SK-300 Shrinking machine steam generator |

|

|

4. SK-300E heat bottle shrinking machine |

|

|

5. CSSG-4 Stainless steel conveyor for water tank containing |

|

Hỏi đáp & đánh giá VAQGF100 3 in 1 Automatic Bottle Filling Machine

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi