Hotline

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar

VAQGF600 3 in 1 Automatic Bottle Filling Machine

Contact

3 in 1 Automatic bottle filling machine VAQGF600

- Capacity: 600 bottles with 20 liters per hour

- Origin: Genuine

- Warranty 12 months

- Free shipping-installation nationwide

Buy now

Free shipping

Request a consultation

Build your own plan

Order, advice 0949.41.41.41 - 0943.41.41.41 (7:30 - 21:00)

Category: FILLING-VAQGF

Product code: VAQGF600

- Describe

- Parameters, configuration

- Picture

Product details

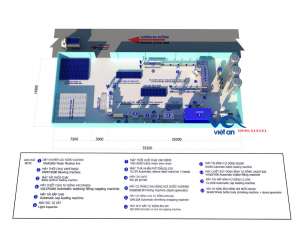

VAQGF 600 3-in-1 automatic bottle filling machine is a high-capacity machine suitable for bottled pure water business units with a capacity of 20L, one day the machine's capacity can reach up to 600 bottles per hour.

VAQGF 600 is the most advanced modern technology from the United States, assembled according to ISO 9001:2015 standards imported and distributed by Viet An Joint Stock Company in Vietnam.

With an increasing demand for mineral water and pure water, the 3-in-1 automatic bottle filling machine VAQGF 600 is a great product for you. With modern functions of the intelligent control system, advanced, maximum energy saving machines have been selected and trusted by many businesses.

Based on your order with machines to bottles, jars filling machine of different capacity, product lines with stainless steel or stainless steel that will have a suitable price. However, the average price of a filling machine ranges from 200 million to several billion VND.

VAQGF 3 in 1 automatic bottle filling machine 600 the bottled pure water solution

Viet An would like to introduce to our customers the new solution of 3-in-1 automatic bottling filling machine VAQGF 600 with intelligent RO water purification technology to help clean the residue to ensure the purest, safe water for people use to ensure standards 6-1: 2010 / BYT: Applies to water used for direct drinking.

Due to the quality of water resources declining while the demand for water is increasingly high. Therefore, to ensure the quality of domestic water in general, especially for drinking water, each business unit should use additional water filtration equipment such as RO, Nano water filters in the reputable and quality assurance establishments like Viet An provide to get clean pure water standards, protect the health of families and relatives in particular and for society in general.

VAQGF 600 automatic 3-in-1 bottle filling machine is equipped with 3 fully automatic stages in a machine, which helps to save maximum installation space, increase productivity, reduce labor.

In addition, with a strong technical improvement, the VAQGF 600 series has the ability to integrate other automatic processes to bring customers a full automatic filling line.

The automatic steps that you can integrate into the VAQGF600 filling machine can be found in the separate self-purchasing stages at the bottom of this article.

The operation process of 3 in 1 VAQGF 600 automatic bottle filling machine

Like the previous 3-in-1 automatic bottle filling machine, the VAQGF600 bottle filling machine is applied with the most modern U.S. filling technology, manufactured at Viet An factory or imported. Direct import from USA, Italia, Taiwan, China.

The machine is retrofitted with a larger number of wash, filling heads and capping heads than smaller machines.

3 automatic stages in a 20L bottle filling machine help manufacturers produce 600 bottles with a capacity of 20 litres of pure water an hour

The process of washing, filling and capping take place completely automatically and synchronously to help ensure hygiene and safety.

Stage 1: Wash in and out of bottles automatically:

The design consists of a chain conveyor system, a bottle holder, a conveyor motor and a 304 stainless steel head pump

5G (20L) bottles without a lid are transferred to the holder, upside down on the holders. The conveyor chain moves the jars thanks to the conveyor motor. In this process, the water from the wash heads in the bottle holder will spray on the bottom of the jar, rinsing the jar. With a high-speed washing system inside and outside the tank, it operates under a smart control panel mounted on the filling machine body. The water to wash in the bottle is pure water and sterilized ozone, ensuring the bottle is clean, sterile to bring to the system of filling heads. 304 stainless steel pump genuine imported from Italy, creating large water pressure to spray, wash inside and outside the jars.

Stage 2: Pour water into the bottle automatically

5G tank (20L) after being washed clean inside and out with pure water and sterilized ozone in stage 1 will be conveyed to the filling heads. In here, with a capacity of 600 bottles of 20L / h, the VAQGF600 bottle extractor is equipped with up to 4 filling heads. More than 1filling head than the VAQGF450 model.

These 4 filling heads are connected to the pure water source through a pipeline system. Plumbing made of high-quality polymer material, durable. When the jar is brought to the position of 4 filling heads, pure water will pass through the filling heads and fill the jar. After filling with water, the flask will be transferred to the capping heads.

Stage 3: Automatic close capping jar

Applying advanced US capping technology, the capping heads are made of steel and plated with stainless steel with 304 high-quality materials, so the service life is over 20 years. The capping head is connected to the cap tray through the cap ducting system. Under piston thrust, the lid will be closed to the jar with sufficient force, ensuring that the jar and the cap are not deformed.

To ensure there is no phenomenon of flipping the lid during the capping process, ensuring the continuity of VAQGF600 bottle filling machine, you should buy an automatic bottle cap loading machine. Details of the cap loading please see below

Other automatic processes can be integrated into the VAQGF600 bottle filling machine

In the tendency of production automation, the use of machines to replace labor workers will help businesses save a large cost in production and business activities. Moreover, labor productivity is high.

The 3-in-1 automatic bottle filling machines provided by Viet An are compatible with other machines to create a modern, fully automated filling line system.

Here are some other machines for the production of 20L bottled drinking water that you can invest in installing after purchasing VAQGF600 filling machine

- Automatic bottle decapping machine BG-1200

This is an extremely modern and intelligent machine, it can replace 2 labor workers.

With the design of 2 cap decapping head. The smart panel automatically operates the machine, automatically shuts down when something goes wrong. The system creates pressure to remove the cap. The frame is made of 100% high quality 304 stainless steel, shiny, no rust, durability over 20 years.

With the function of quickly removing the lid from the bottle cover without deforming the lid to be able to reuse the lid to save costs.

Establishments producing 20L bottled drinking water usually buy the bottles back for reuse, save costs, so use this machine. Instead of hiring workers to remove the cap, it is not guaranteed productivity and at the same time does not guarantee the quality of the cap.

Specifications of BG-1200 automatic decapping machine

|

Model |

BG-1200 |

|

Capacity (jar / h) |

900-1200 |

|

Wash head |

2 |

|

Electricity supply |

Use Air |

|

Pressure (Mpa) |

0.8-1.0 |

|

Dimensions (LxWxH) |

800x750x1800 |

|

Weight / kg) |

120 |

|

Price (USD) |

|

2. ST-600 Automatic outside bottle brushing machine

Model ST-600 is the machine that comes with automatic decapping machine BG-1200. After the bottle is removed, it should be rinsed clean before being transferred to the 3-in-1 filling machine VAQGF600.

With the design of 5 bottle wash heads, the bottle brush system can automatically rotate 180 degrees to wash from the neck, bottle body, bottom of the 20L bottle without involving labor.

When using this automatic external washing machine ST-600 you will save the cost of hiring 2 workers

Besides, you also take advantage of the wastewater of the RO membrane to help save maximum costs. Machine can wash 450-600 bottles per hour.

Specifications of ST-600 Automatic outside bottle brushing machine

|

Model |

ST-600 |

|

Capacity (jar/h) |

450-600 |

|

Wash head |

5 |

|

Power (kw) |

1.2-1.5 |

|

Pressure (Mpa) |

0.7-0.8 |

|

Dimensions (LxWxH) |

1850x1100x1800 |

|

Weight / kg) |

230 |

|

Price (USD) |

|

- BL-600 automatic bottle loading machine:

With a capacity of 600 5G jars, you need to hire at least 1 worker to transport the jar shell into a 3-in-1 VAQGF600 bottle filling machine. Now with this automatic loading machine with 4 load heads, you can load 4 jars at the same time without labor. The machine has a life of up to> 20 years. Currently, this device is supplied by Viet An to the market at a price of 65 million VND. So if you just take a rough look, every month you will save about 7 million VND to hire 1 worker. Less than 1 year, you can save enough money to invest in buying the machine. And the remaining 19 years is the cost that you can save to reinvest, expand production, increase competition.

Specifications of BL-6000 automatic bottle loading machine:

|

Model |

BL-600 |

|

Capacity (jar/h) |

600 |

|

Wash head |

4 |

|

Power (kw) |

0.75 |

|

Dimensions (LxWxH) |

1650x960x1200 |

|

Weight / kg) |

100 |

|

Price (USD) |

|

- Automatic cap loading machine CL-1200:

As we mentioned above, if you only invest in a 3-in-1 machine, the bottle cap will be poured into the tray by the worker. This has a limitation: the lid can be flipped at a rate of 3-5%. This will affect the production process of pure water bottles, costly. In addition, workers also need to monitor the capping process regularly.

The automatic bottle cap loading machine CL-1200 is born, which will guarantee 100% of the bottle caps will not flip, workers do not have to pay much attention. All the process of filling the lid when it is lacking and stop filling the lid when it is full in the duct leading to the capping system will be undertaken by the automatic bottle loader CL-1200. Thanks to the air blowing system mounted on the conveyor, 100% of the bottle cap when putting into the cap duct is in the right direction. Bottlecap tray has a large capacity, on average 1 shift only need to fill the cap once.

Specifications of CL-1200 Automatic cap loading machine

|

Model |

CL-1200 |

|

Capacity (lid / h) |

300-1200 |

|

Power (kw) |

0.18 |

|

Dimensions (LxWxH) |

600*600*3000 |

|

Weight / kg) |

65 |

|

Price (USD) |

|

5. Light inspection (DJ-100)

The purpose of the DJ-100 is to detect probabilities. In the process of Bottled drinking water is an area that requires very high food safety and hygiene. The detection of strange objects in the bottle, the detection of water bottles that do not meet the standards is very necessary to always bring to market the good quality 20L water bottles, you should use this light inspection DJ-100. The machine has a light system to help detect the probability of water bottles in production. You can randomly check the water bottles bypassing these 20L bottles through this DJ-100 light inspection. The machine's searchlight system will help you see clearly whether the jar is mixed with strangle objects or not, quality or not. In order to remove poor quality water bottles go out.

Specifications of DJ-100 light inspection

|

Model |

DJ-100 |

|

Power (w) |

3 x 20w |

|

Dimensions (DxRxCmm) |

600x200x1000 |

|

Price (USD) |

|

- SK-600E heat bottle shrinking machine

Applying the most modern shrinkage technology in 2021, the SK-600E model is designed to use electricity to create heat effect on the shrink film, helping to shrink the film into the body of the bottle quickly, beautifully, without wrinkles. A special feature of this machine is the ability to self-adjust the temperature, always ensuring a stable heat level in the shrink chamber, so the quality of the shrink film on the bottle is always guaranteed.

Specifications of SK-600 heat bottle shrinking machine

|

Model |

SK-600E |

|

Capacity (jar / h) |

500-600 |

|

Power(kw) |

20 |

|

Size (DxRxCmm) |

3300x650x800 |

|

Price (USD) |

|

- Plastic conveyor for empty jars CSG-6.

The plastic conveyor system is designed to consist of a conveyor motor, a plastic conveyor and a frame hold conveyor.

With a length of 6 m and a width of 29 cm, this plastic conveyor will help you move empty jars quickly, without labor.

This plastic conveyor can be used to connect the process of decapping, washing outside the bottle with a 3-in-1 filling machine

Technical specifications of Plastic conveyor for empty jars CSG-6

|

Model |

CSG-6 |

|

Power(kw) |

0.55 |

|

Size (DxRxCmm) |

6000x290 |

|

Price (USD) |

|

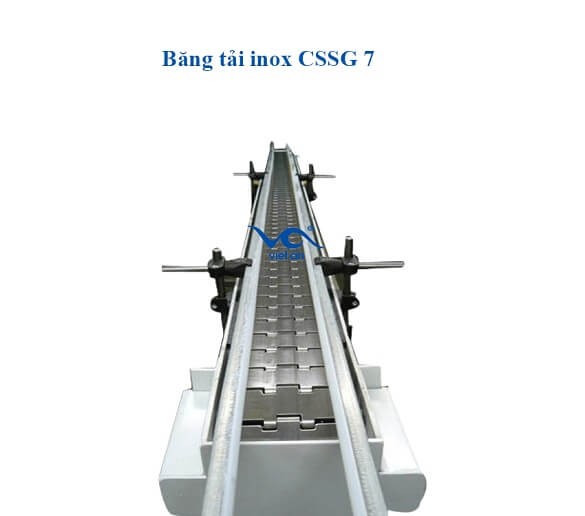

8. Stainless steel conveyor CSSG-7:

The operating principle of stainless steel conveyor is similar to the plastic conveyor, however, because stainless steel conveyor has a high bearing capacity, high durability. So they are used to transport water bottles that have been filled with water.

The stainless steel conveyor CSSG-7 has a size of 7m and a width of 29 cm, so it does not more occupy the installation area. This unit is often used to connect 3-in-1 automatic bottle filling machine to other stages such as shrinking the bottle with heat ...

Specifications of CSSG-5 Stainless steel conveyor

|

Model |

CSSG-7 |

|

Power(kw) |

0.75 |

|

Size (DxRxCmm) |

7000x290 |

|

Price (USD) |

|

Viet An's commitment when customers buy 3-in-1 automatic bottle filling and filling machine VAQGF 600

When customers buy 3-in-1 automatic filling machine VAQGF 600 in Viet An will have a 1-year warranty, long-term maintenance, free of charge and shipping to 64 provinces and cities nationwide (except islands).

Because VAQGF 600 automatic 3-in-1 bottle filling machine is applied from advanced technology, the machine can save up to 45% power compared to other conventional filling lines, calculated annually VAQGF 600 can save hundreds of millions for businesses. In addition, the device is also designed with strong iNox 304, shiny, machine life of 20 years.

Customers who buy the device will experience thoughtful caring service, enjoy many attractive promotions, and many valuable gifts.

VAQGF 600 3-in-1 automatic bottle filling machine has full certification, genuine product commitment. Viet An is committed to saying NO to Counterfeit-Quality goods

In order for the 20L bottle filling and bottling system to run stably, ensuring the capacity, it is a mandatory requirement that you need to prepare a 3-phase power line system.

Customers need to contact the hotline: 0942 41 41 41 immediately for advice and support on 3-in-1 automatic bottle filling machine VAQGF 600 quickly and accurately.

See more article details

Specifications of 3 in 1 Automatic jar filling machine VAQGF600

20l JAR FILLING MACHINE VAQGF600 – 3 STAGES MUST BE BUYED

|

Model |

VAQGF600 |

|

Extraction head |

550-600 |

|

Head swirled |

4 |

|

Power capacity (kw/h) |

17 |

|

Pressure (Mpa) |

0.8-1.0 |

|

size (D*R*Cmm) |

4900x2200x2110 |

|

Weight (Kg) |

1600 |

|

Feature |

Water heating to 60 ° C |

|

Price (USD) |

|

SEPARATE PURCHASE STAGE INTEGRATED INTO A 3 IN 1 JAR FILLING MACHINE VAQGF600

|

Model |

Price (USD) |

|

1. BG-1200 automatic cap decapping machine |

|

|

2. ST-600 Automatic bottle washing machine |

|

|

3. BL-600 Automatic jar loading machine |

|

|

4. CL-1200 Automatic cap loading |

|

|

5. DJ-100 light inspection |

|

|

6. SK-600E heat bottle shrinking machine |

|

|

7. CSG-6 Plastic conveyor for empty jars |

|

|

8. CSSG-7 Stainless steel conveyor for water tank containing |

|

Hỏi đáp & đánh giá VAQGF600 3 in 1 Automatic Bottle Filling Machine

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi