Hotline

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar

VAGGF2500 Glass Bottle Carbonated Drink Filling Machine

Contact

Glass Bottle Carbonated Drink Filling Machine VAGGF2500 with a capacity of 2500 bottles / h

- Capacity: 2500 Bottles / h

- 4 automatic stages

- Standard: ISO 9001:2015

- Origin: Genuine

- Warranty 12 months

- Free shipping-installation

Buy now

Free shipping

Request a consultation

Build your own plan

Order, advice 0949.41.41.41 - 0943.41.41.41 (7:30 - 21:00)

Category: FILLING-VAGGF

Product code: VAGGF2500

- Describe

- Parameters, configuration

- Picture

Product details

In order to bring carbonated soft drinks such as beer, wine, energy drinks into glass bottles, enterprises should use the chain of 4 in 1 automatic glass bottle carbonated drink filling machine VAGGF2500 of Viet An.

Always taking the lead in updating new technologies for the production of beverages today, Viet An General Trading Joint Stock Company is proud to be the No.1 unit in Vietnam in importing, manufacturing, distributing and installing the best types of glass bottle carbonated drink filling machine in Vietnam and other countries in Southeast Asia.

With any carbonated beverage, its taste is the highlight to attract consumers. While beer, alcohol and other carbonated beverages in plastic bottles will be very volatile, the taste of the drink is no longer the original. This greatly affects the consumption of the product.

Do not cause any chemical reaction to the contents inside, keep the flavour of carbonated drinks, minimize the evaporation of CO2 is the advantage of all kinds of glass bottles.

Therefore, more and more businesses use glass bottles with carbonated drinks instead of using PET bottles.

Currently, Viet An is bringing to market the glass bottle carbonated drink filling machine with capacity from 2500 bottles to 8000 500ml bottles per hour.

In this article, Viet An will introduce in detail the 4-in-1 automatic pressure filling machine specially designed to pour carbonated water into glass bottles with a capacity of 2500 bottles / h VAGGF2500.

What is outstanding in glass bottle carbonated drink filling machine with 500ml VAGGF2500 glass bottle?

- Applying the most modern glass bottle filling technology 2019

- 4 automatic stages to increase productivity and reduce labour

- Standard of manufacturing VAGGF2500 extraction machine with ISO 9001:2015

- Easy to operate, easy to maintain

- Automatic bottle filling process, ensuring food safety

- High capacity can fill 2500 glass bottles of 500ml / h

- Machine frame, filling heads, capping parts ... they are made of high-strength SUS304 stainless steel material, absolute safety

4 automatic steps integrated into the glass bottle filling machine VAGGF2500

Stage1: Air conveyors

This is the part that connects to the 3 in 1 pressure filling machine.

Function:

Air conveyor has a length of 2m. 1 head of the air conveyor attach air fan at the top of the support bar. 1 head of the conveyor attached to the washing machine, filling and capping the bottle 3 in 1. when the glass bottle is delivered to the bottleneck bar support of the air conveyor, the fan operates, acting on the glass bottles to push the bottle away and put the glass bottles together. With high capacity, absolute accuracy.

Stage 2 + 3 + 4: Rinse wash-filling- 3 in 1 bottle capping

Glass bottle filling machine is equipped with 14 rinse heads, 12 filling heads and 4 capping heads. On average, 2,500ml glass bottles will be washed, extracted and caping per hour.

Like other types of carbonated water filling machine, the VAGGF2500 model provided by Viet An is also designed to fill carbonated drinks into glass bottles according to the principle of pressure filling.

A special feature of this machine is the ability to customize bottle size, bottle height. When you want to change the types of bottles you just need to replace the corresponding bottle moulds.

Smart control panel, users can easily adjust, change the operating parameters of the machine. And easily check the installed information via the PLC touch screen

When air conveyors transport glass bottles to the 3 in 1 machine. Here the gear conveyors move the glass bottles to the rinsing heads. With the principle of continuous rotation around the fixed axis, the glass bottles will be held by the bottlenecks and turned 180 degrees back into the rinsing heads. Under high water pressure from the air compressor, the water will spray up into the bottle to wash away the dirt clinging to the bottle. After being cleaned, the clamps heads will be turned back 180 degrees and returned to the filling part.

In here, with 12 filling heads will bring the carbonated drinks into the bottle quickly, according to the programmed norms.

The gear conveyors continue to bring the glass bottle to the capping unit. Here, 4 capping heads will close all aluminium caps into glass bottles and move to the next stage.

Automatic stages purchase separately

In addition to the 4 automatic stages available from VAGGF2500, you can invest more

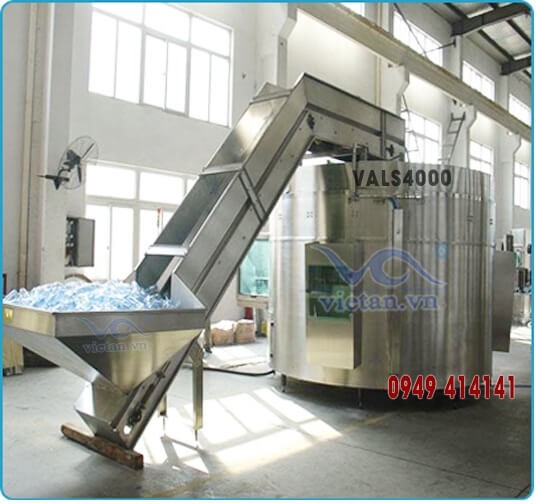

1. Bottle loading and bottles arrange machine

Designed machines include bottle trays, bottle moulds and conveyor systems.

The main function is to automatically bring the bottle to the air conveyor instead of the labour. Automatically arrange glass bottles.

Specifications of Bottle loading and bottles arrange machine

|

Model |

VALS4000 |

|

Machine capacity (BPH) |

2000-4000 |

|

Bottle type - 2 moulds (ml) |

300-1500 |

|

Electrical capacity (kW / h) |

0.75 |

|

Size (D * R * C mm) |

1200X1500X900 |

|

Weight / kg) |

150 |

|

Price (USD) |

5,900 |

After-sales service of Viet An

When you trust and choose Viet An to supply and install automatic glass bottle carbonated drink filling machine.

You will get 100% free shipping and installation costs

Time from the signing of the supply contract to the installation of the bottle filling machine and handover of the machine to customers within 1 week.

Warranty and maintenance policies

Glass bottle pressure filling machine supplied by Viet An is guaranteed for 12 months and long-term maintenance.

In addition, customers also enjoy policies such as 5-10% discount of the total cost when buying other machines provided by Viet An such as bottle blowing machine, water filter line, ice making machine ...

Commitment to quality VAGGF2500 glass bottle filling machine

Viet An General Trading Joint Stock Company with nearly 20 years of construction and development experience, has always been the top 100 leading enterprises in the country in supplying automatic carbonated water filling machines with glass bottles, genuine high quality. Since its establishment, Viet An has received many medals and certificates of product quality.

Some cups that Viet An has achieved

Continuously trying and perfecting, we always bring to customers the high-tech industrial machinery products, produced in the most modern technological lines and quality management ISO 9001:2015

Viet An has 2 factories in Hanoi, Da Nang and offices in Hanoi, Ho Chi Minh, Da Nang and Buon Ma Thuot. So when you need to be consulted to learn about automatic filling machines. Come to the nearest branch of Viet An for the fastest support. Or you can call the hotline number of Viet An 0942 414141

See more article details

Specifications of glass bottle carbonated drink filling machine VADGF2500

A. GLASS BOTTLE CARBONATED DRINK FILLING MACHINE VAGGF2500- 4 STAGES MUST BE BUYED

|

Model |

VAGGF2500 |

|

Wash head |

32 |

|

Extraction head |

32 |

|

Head swirled |

10 |

|

Power capacity (kw/h) |

3 |

|

Pressure (Mpa) |

0.4-0.6 |

|

Bottle size (mm) |

Tuỳ chỉnh |

|

Bottle height |

Tuỳ chỉnh |

|

Electricity supply |

Tuỳ chỉnh |

|

3 in 1 size (D*R*Cmm) |

3220*2500*2750 |

|

Weight (Kg) |

4950 |

|

Air conveyor |

2000 |

|

Bottle cap loading machine (D * R * Cmm) |

1200*950*3000 |

|

light inspection (D*R*Cmm) |

600*200*1000 |

|

Plastic conveyor (D*R*Cmm) |

2000 |

|

Price (USD) |

|

B. SEPARATE PURCHASE STAGE INTEGRATED INTO A 4 IN 1 FILLING MACHINE- VAGGF2500

|

Model |

Price (USD) |

|

1. Bottle loading and bottles arrange machine - VALS4000 |

|

Hỏi đáp & đánh giá VAGGF2500 Glass Bottle Carbonated Drink Filling Machine

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi