Hotline

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar

VAQGF900 3 in 1 Automatic Bottle Filling Machine

Contact

3 in 1 Automatic bottle filling machine VAQGF900

- Capacity: 900 bottles with 20 liters per hour

- Origin: Genuine

- Warranty 12 months

- Free shipping-installation nationwide

Buy now

Free shipping

Request a consultation

Build your own plan

Order, advice 0949.41.41.41 - 0943.41.41.41 (7:30 - 21:00)

Category: FILLING-VAQGF

Product code: VAQGF 900

- Describe

- Parameters, configuration

- Picture

Product details

3-in-1 automatic bottle filling machine VAQGF 900. With the pure bottled and bottled pure water business units, Viet An has been providing them with the best solutions for purifying water treatment. as well as fast water filling, quality assurance. The machine is one of the specialized products for bottling and has been chosen by many bottled pure water producing units.

Viet An General Trading Joint Stock Company is an established company with 20 years of experience in importing and distributing the most modern and advanced industrial machinery in the world.

We are a leading enterprise in the import and distribution of industrial RO pure water filtration lines and bottling machines, automatic bottling, manufacturing stainless steel ice machines Exporting brands of VA, USApec, Vinaro is No. 1 quality in Vietnam.

With 3 automatic stages, when using this automatic filling machine, your business will save a lot of labor costs, increase the productivity of bottled drinking water to the market and most importantly, ensure standards on food hygiene and safety.

Introduction of 3-in-1 automatic bottle filling machine VAQGF 900

3-in-1 automatic bottle filling machine VAQGF 900 is a 900-bottle filling machine per hour. The machine is manufactured at Viet An factory or imported directly from the USA, Italia, Taiwan, China. The machine is manufactured according to the most stringent ISO 9001:2015 standard today.

Currently, there are many units offering different types of filling machines, so customers should also pay attention to the most appropriate choice as well as the price, quality of the warranty, maintenance of the machine. Coming to Viet An, all of the above factors are met in a great way. We always consider customers the existence of the company so always put the TRUST and RESPONSIBILITY of the business first.

3-in-1 automatic bottle filling machine VAQGF 900 is made of 304 stainless steel, the material has extremely high durability, the service life of the machine can be up to 20 years. However, to achieve the highest productivity and long-term use, customers should also pay attention to regular cleaning of machines, maintenance to achieve the best efficiency.

3 automatic stages in one VAQGF900 machine

Stage 1: Automatic bottle rinse

Function:

Wash inside and outside of bottles automatically

Make sure the jar shell is clean and sterile

With the use of washing inside and outside of bottles, hygienic jar, the washing unit is equipped with a conveyor system, a system of bottle holders and a 304 stainless steel head booster pump.

The 20L bottle jars without a lid are transferred to the bottle holder. The chain conveyor will operate by the conveyor motor. In the process of moving the bottle, the water at the washing heads will spray inside and outside the bottle, rinsing it. The source of water for washing bottles is pure water and sterilized ozone. Make sure the bottle after cleaning is completely clean and completely sterile

Stage 2: Pour pure water into the 20L jars automatically

Model VAQGF900 is equipped with 6 filling heads. These filling heads are made of high quality 304 stainless steel with high durability. On each filling head, there is an induction system so that when the water reaches a certain level, it will stop filling the bottle.

Filling speed up to 900 bottles 20L/h

You can adjust the filling speed by adjusting the button on the control system mounted on the body.

On the control panel, the PLC touch screen shows the operating parameters of the machine so that the operator can easily observe

Stage 3: Close the cap automatically

The 20L jars after being filled with water in stage 2 will be transferred to the capping heads. With high quality 304 stainless steel, use pressure to close the cap on the jar. In the capping part, there is a cap duct system to connect to the cap tray system so that workers can supply the lid for the capping process to achieve high performance.

With a capacity of 900 bottles, you should invest to buy an automatic bottle loader to ensure a stable and accurate cap.

With this 3-in-1 automatic washing machine, filling and capping machine VAQGF900, you will save 7-10 employees, increase efficiency and competitiveness for businesses.

Some stages can be integrated with VAQGF900 3 in 1 jar filling machine

VAQGF900 automatic filling machine is one of the most powerful and modern filling machine on the market today. When investing in this machine in addition to the 3 automatic built-in stages, the machine also has the ability to integrate with other automatic stages without affecting the productivity of the machine.

- BG-1200 automatic decapping machine

Function: Remove the cap from the jar

Capacity: 900-1200 lids / h

Structure: 2 withdraw cap heads

Bottles that have been collected will need to be removed from the container to reuse. If using labor, it will take time, the cap is not intact so it is difficult to reuse.

Model BG-1200 is completely different, with pressure of 0.8-1.0 Mpa will impact on the lid and easily remove the cap from the jar without deforming the shape of the cap. The bottle cap after being drawn will be reused to save

With the modern costs design, a material frame is 304 stainless steel easy to clean, durable

Specifications of BG-1200 automatic decapping machine

|

Model |

BG-1200 |

|

Capacity (jar / h) |

900-1200 |

|

Wash head |

2 |

|

Electricity supply |

Use Air |

|

Pressure (Mpa) |

0.8-1.0 |

|

Dimensions (LxWxH) |

800x750x1800 |

|

Weight / kg) |

120 |

|

Price (USD) |

|

- ST-1200 Automatic outside bottle brushing machine

With the ability to wash bottles with high-speed thanks to the design of 9 wash heads, can wash the bottle quickly and clean completely automatically. The bottles are removed, taken to the washing machine outside of this ST-1200 automatic bottle, the brush system is capable of rotating 180 degrees so that the bottle will be washed from top to bottom.

The most outstanding feature of this machine is its ability to save electricity. Although operating with a capacity of 900-1200 jars 20L / h only 1.5kw electricity. Much more energy-efficient than other conventional washing machines on the market.

Specifications of ST-1200 Automatic outside bottle brushing machine

|

Model |

ST-1200 |

|

Capacity (jar/h) |

900-1200 |

|

Wash head |

9 |

|

Power (kw) |

1.5 |

|

Pressure (Mpa) |

0.7-0.8 |

|

Dimensions (LxWxH) |

2000x8000x1800 |

|

Weight / kg) |

260 |

|

Price (USD) |

|

- BL-900 automatic bottle loading machine:

The machine is designed with 6 loading heads, which helps to load a higher capacity jar shell than other previous loading machines. This tanker loader will be integrated into the VAQGF900 3-in-1 bottle filling machine to help automate the production process.

100% material of the machine is high grade 304 stainless steel, no oxidation, no rust, high durability

Specifications of BL-900 automatic bottle loading machine:

|

Model |

BL-900 |

|

Capacity (jar/h) |

900 |

|

Wash head |

6 |

|

Power (kw) |

0.75 |

|

Dimensions (LxWxH) |

1950x960x1200 |

|

Weight / kg) |

110 |

|

Price (USD) |

|

- Automatic cap loading machine CL-1200:

Function: Automatic loading of a cap, providing caps for capping unit

The machine is designed with a tray caps with a large capacity of thousands of caps

Operating procedure of the machine. Workers pour caps into the tray of the cap loading machine. Under the operation of the conveyor motor, the cap will be moved automatically to the position of the duct connected to the 3-in-1 bottle cap filling machine VAQGF900. At the interlocking position, on the conveyor cover, there is a magic eye system to control the number of caps. There is a system of blowing air to blow the cap into the duct in the right direction.

When using this cap loading machine, it will ensure that 100% of the lid is not overturned. With the eye sensor system, the conveyor will automatically replenish the lid when it is missing and stop supplying the lid when it is full in the duct leading to the capping part.

Specifications of CL-1200 Automatic cap loading machine

|

Model |

CL-1200 |

|

Capacity (lid / h) |

300-1200 |

|

Power (kw) |

0.18 |

|

Dimensions (LxWxH) |

600*600*3000 |

|

Weight / kg) |

65 |

|

Price (USD) |

|

5. Light inspection (DJ-100)

With the design of 2 lights, when checking into the water jar, the worker will see clearly jar what has a strange object. This will remove the unsecured water jars before going to other stages.

Benefits of the machine: Ensuring quality monitoring of water bottles for manufacturers

Specifications of DJ-100 light inspection

|

Model |

DJ-100 |

|

Power (w) |

3 x 20w |

|

Dimensions (DxRxCmm) |

600x200x1000 |

|

Price (USD) |

|

- SK-1200E heat bottle shrinking machine

When you have invested in VAQGF900 automatic bottle filling machine with a capacity of 900 bottles of 20L per hour, we recommend that customers should invest in a heat shrink film machine with SK-1200E model.

With the principle of extremely smart operation, after the worker takes a polymer film into the whole body of the bottle, the bottle will go through the heat shrinking chamber of the machine. With the heat of electric heat, the film will adhere to the bottle without wrinkling.

Specifications of SK-1200 heat bottle shrinking machine

|

Model |

SK-1200E |

|

Capacity (jar / h) |

900-1200 |

|

Power(kw) |

36 |

|

Size (DxRxCmm) |

4300x650x1100 |

|

Price (USD) |

|

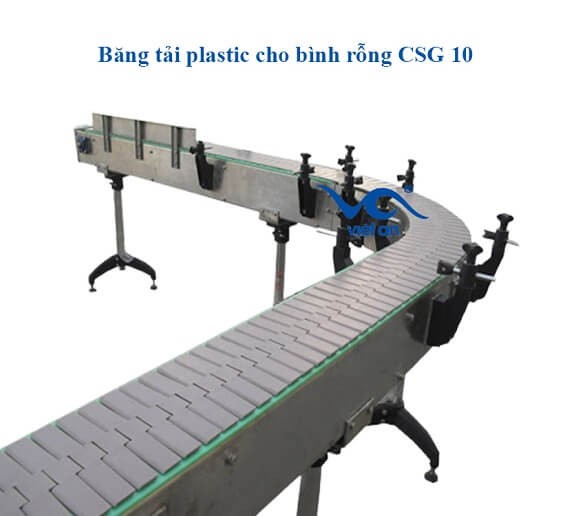

- Plastic conveyor for empty jars CSG-10.

The plastic conveyors will help customers do not need labor to transport the jar shell from one location to another while saving production space. The plastic conveyor is cheap, suitable for many manufacturers. Conveyor durability of over 15 years

Note: The plastic conveyor is only suitable for moving empty jars to ensure the service life of the conveyor.

Specifications of Plastic conveyor for empty jars CSG-10

|

Model |

CSG-10 |

|

Power(kw) |

1,1 |

|

Size (DxRxCmm) |

10000x290 |

|

Price (USD) |

|

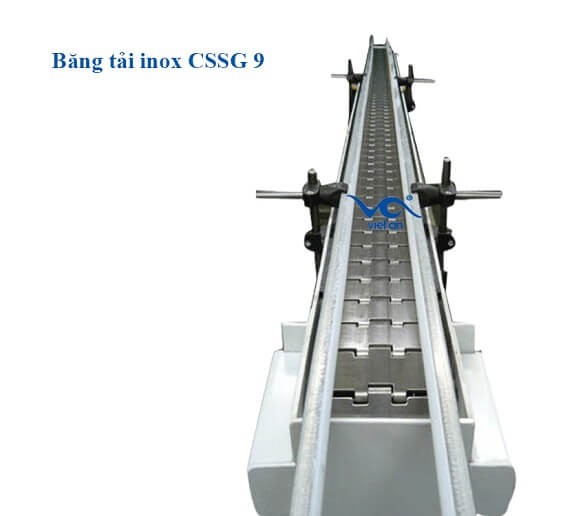

8. Stainless steel conveyor CSSG-9:

With higher durability, load capacity is much better than plastic, so stainless steel conveyors you can use to move water-filled jars from one stage to another without need labor workers. The life of stainless steel conveyor is up to over 20 years.

Specifications of CSSG-9 Stainless steel conveyor

|

Model |

CSSG-9 |

|

Power(kw) |

0.75 |

|

Size (DxRxCmm) |

9000x290 |

|

Price (USD) |

|

The difference of 3 in 1 automatic bottle filling machine VAQGF 900

- The machine is manufactured using the most modern bottle filling technology of the United States

- The fast filling process with 3 automatic stages

- The intelligent control panel automatically switches off when something goes wrong

- Assembly process meets ISO 9001:2015 standard

- Filling process is an automatic, closed to ensure food hygiene and safety standards QCVN 6-1:2010/BYT of the Ministry of Health

- VAQGF 900 3-in-1 automatic bottle filling machine designed in a compact, industrial-friendly design

- The machine runs stably, maximizing power consumption

- The machine is warranted for 1 year and long-term maintenance

Excellent remuneration when buying 3-in-1 automatic bottle filling machine VAQGF 900 in Viet An

Come with us to own the best products. With the greatest deals, none have. With:

- The product warranty period is up to 12 months

- Permanent maintenance

- Professional and enthusiastic staff

- Experienced engineer team

- And quick installation team.

VAQGF 900 3-in-1 automatic bottle filling machine- perfect choice

Model VAQGF 900, the number 900 corresponds to a capacity of 900 bottles of 20 liters/hour. Filling machine is manufactured by modern filling technology of the United States and is assembled in the USA, Taiwan, Shanghai according to ISO 9001:2015 and directly distributed by Viet An.

The main use of the device is for filling, quantifying, automatic and fast bottling, ensuring food hygiene and safety standards for bottled water of the Ministry of Health.

VAQGF 900 3-in-1 automatic bottle filling machine is designed quite compact, does not make the manufacturer take up too much area, modern design with 304 stainless steel material for the machine to look more beautiful and firm, have a longer shelf life.

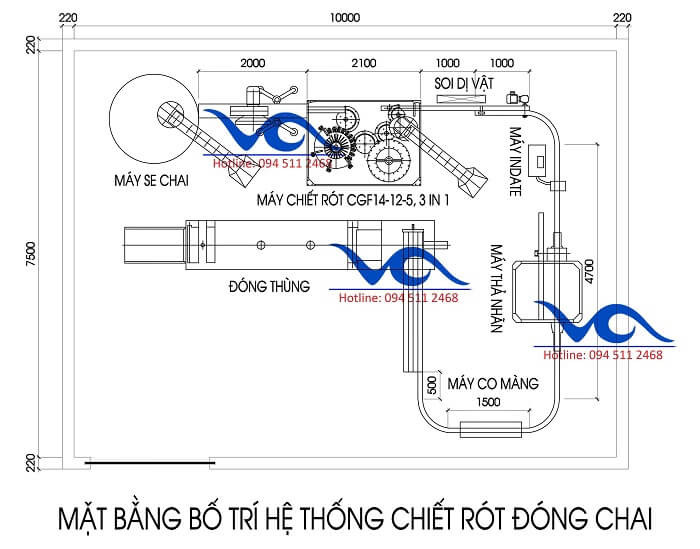

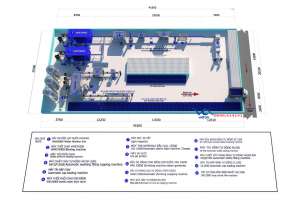

Installation surface for automatic filling machine 3 in 1 VAQGF 900

With a compact industrial design, does not take up too much space. But to ensure strict standards for food hygiene and safety as well as other requirements for a bottled pure water business. If you intend to install 3 in 1 VAQGF 900 automatic bottle filling machine, you need to prepare a ground as instructed below.

Nearly 20 years of construction and growth, Viet An General Trading Joint Stock Company is the leading company in Vietnam in supplying filling machines, water filtration lines, producing ice machine ...

Viet An filling machine products not only lead the filling equipment market in Vietnam but also enter the world market such as Laos, Cambodia...

Whenever you need advice on using or buying a 3 in 1 VAQGF 900 automatic bottle filling machine, please contact Viet An: 0942.41.41.41

See more article details

Specifications of 3 in 1 Automatic jar filling machine VAQGF900

- 20l JAR FILLING MACHINE VAQGF600 – 3 STAGES MUST BE BUYED

|

Model |

VAQGF900 |

|

Extraction head |

820-900 |

|

Head swirled |

6 |

|

Power capacity (kw/h) |

20 |

|

Pressure (Mpa) |

0.8-1.0 |

|

size (D*R*Cmm) |

5200x2230x2110 |

|

Weight (Kg) |

2800 |

|

Feature |

Water heating to 60 ° C |

|

Price (USD) |

|

- SEPARATE PURCHASE STAGE INTEGRATED INTO A 3 IN 1 JAR FILLING MACHINE VAQGF900

|

Model |

Price (USD) |

|

1. BG-1200 automatic cap decapping machine |

|

|

2. ST-1200 Automatic bottle washing machine |

|

|

3. BL-900 Automatic jar loading machine |

|

|

4. CL-1200 Automatic cap loading |

|

|

5. DJ-100 light inspection |

|

|

6. SK-1200E heat bottle shrinking machine |

|

|

7. CSG-10 plastic conveyor |

|

|

8. CSSG-9 Stainless steel conveyor for water tank containing |

|

Hỏi đáp & đánh giá VAQGF900 3 in 1 Automatic Bottle Filling Machine

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi