Hotline

10 tons ice cube making machine made in Hue

10 ton ice making machine is a product of Viet An which is manufactured according to the latest technology in 2019. From 100% new components manufactured according to ISO9001-2015 standards. With outstanding advantages, Viet An is proud to be the best supplier of quality ice making machines in Vietnam.

Recently, Mr Truong from Hue had a chance to visit Viet An's factory in Quang Minh Industrial Zone - Me Linh - Hanoi. Visiting the production model directly here, Mr Truong decided to sign a contract to buy 10-ton ice machine - IVA10T with Viet An General Trading Joint Stock Company.

10-ton ice cube making machine for Mr Truong

Viet An is a company established with nearly 20 years of experience in the field of manufacturing and supplying industrial machines such as ice making machine, water filtration line, filling machine, bottle blowing machine, jar blowing machine. .. We are committed to bringing our customers the best quality products. With the best preferential price, the same after-sales service, professional dedicated service, and many attractive gifts, discount cards for every customer coming to us.

Throughout the history of establishment and development, with the continuous efforts of all Viet An employees, they have achieved great achievements & continuously developed, completed the mission for customers and contributed significant for industrial machinery industry in Vietnam and ASEAN countries. With these achievements, Viet An has been honored to receive many prestigious awards.

Outstanding advantages of 10-ton ice making machine is suitable for Mr Truong's needs

100% new compressor: Considered as the heart of 10 tons ice making machine. The compressor used in Viet An 10 tons ice making machine is 100% new compressor. Specially designed by Viet An for Viet An industrial ice machine. Currently on the Vietnamese market, only Viet An ice machine has 100% new compressor. This compressor has been tested extremely strictly. It is manufactured on fully automatic CMC system, cutting, stamping, automatic moulding. Each compressor is tested with absolute accuracy without any small errors.

The compressor is 100% new

Uses of the compressor

- The use of cooling capacity control for ice making machines

- Control and save power consumption for you

- Helps make the service life of the device more durable, longer

- Control the temperature and keep the safety of the cooling system stable

- Making ice cube machine works smoothly, runs smoothly, makes less noise.

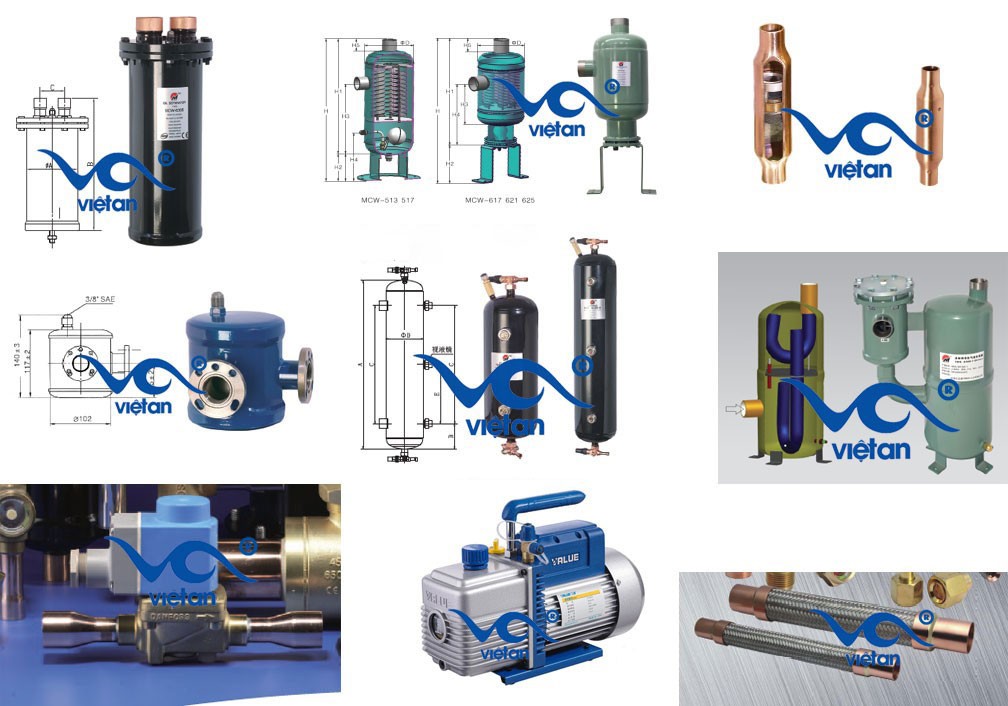

liquid and air separation system (the first technology applied by Viet An for industrial ice making machine). In the past, before this part was available, the pipes of the ice machine would be designed in the style of the chicken gut - but when this technology was applied they would help minimize the pipeline, the ice making machine was designed more neatly. Viet An's air separation system has the ability to remove fluid and return it to the air way. Prevent the compressor from becoming liquid infected. Helping the compressor not defective and the service life of the compressor is much higher. The compressor used for ice machine is an air compressor. So the compressor that pushes out must be gas, and the suction must be air. The gas that is produced is hot air and the gas that is drawn in is cold air. Therefore, the inlet gas must not be contaminated with liquid (water or oil). If the suction air is contaminated with liquid, it will lead to a decrease in compressor durability.

Air separation system

Condenser: This product is directly imported by Viet An, committed to always have the best price. The condenser in a pure ice making machine is responsible for condensing superheated gas after compressor into refrigerant liquid state. The operation of the condenser has a decisive effect on the condensation pressure and temperature and thus affects the efficiency and safety of the entire refrigeration system in the industrial ice making machine.

Cooling tower: Cooling tower is responsible for transferring excess heat of the water to help cool quickly and save energy. The good cooling system helps industrial ice machine to operate stably and durable.

INox pump system: made of 304 stainless steel, imported exclusively by Viet An. Currently, only ice-making machines of Viet An use iNox 304 pump. All ice machines on the market use cast iron pumps so the price will always be cheaper. That means the durability will not be high.

Automatic electrical system: 10-ton ice making machine has an automatic electrical system that helps the machine operate the entire process of ice making machine, automatically disconnects when there is an electrical problem, automatically adjusts ice making time. to have satisfied hollow ice.

Automatic electrical system

stop valve system imported 100%

Exclusive components are only available on 10-ton industrial ice making machines

The manufacturing process of IVA10T 10-ton ice cube making machine

Step 1: Water through the filtration process (customers should choose a regulated water source such as well water, underground water ...) Pump water into the lower water reservoir, located below the ice mortar.

Step 2: Use a water pump system made from iNox, to transfer water from the lower tank to the upper one, then let the water through the condenser system, which is the superheated gas condensate. after compressor into the liquid-state refrigerant. The operation of a condenser has a decisive effect on the pressure and temperature of the condenser and thus affects the efficiency and safety of the entire refrigeration system in the ice making machine.

Step 3: Direct this liquid into the ice pipes inside the millstone (located below the upper water reservoir).

Step 4: The compressor will start operating, combined with the refrigerant R22 in the iNox IVA10T ice cube machine - to transfer cold air into the ice tube (the temperature is now about minus 20 degrees C), clear water The tube will gradually crystallize into a rock and stick to the inside of the tube wall.

Step 5: After a period of 40 minutes to 45 minutes, ice cubes have been formed, the compressor system will reverse to pump hot air into the ice mortar, helping to separate a thin layer of rock to let the ice fall from the tube.

Step 6: After the ice leaves the tube, it will be cut by the knife system below the ice mortar, cut the ice into with pre-set size.

Warranty policy for 10 ton industrial ice making machine

During the use period of 12 months from the date of purchase of the 10-ton ice machine, if there are any technical problems of the manufacturer, Viet An will provide a completely free warranty for Mr Truong.

After a 12-month warranty period, Viet An has a regime of maintenance, machine testing, and periodic water quality for Mr Truong completely free.

Offering shipping costs package is a free installation of products for Mr. Truong.

Many attractive gifts come with special discounts when Mr Truong needs to buy the next products of Viet An.

Warranty time, quick maintenance, support to answer his questions 27/7.

With the advantages and attentive service of Viet An, Mr Truong will soon create a brand for his business. Thank you for trusting and travelling with Viet An. Customers wishing to buy 10 ton ice making machine or any capacity from 1 ton to 100 tons, please contact Viet An today to receive the most attractive offers. Hotline:

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar

Hỏi đáp & đánh giá 10 tons ice cube making machine made in Hue

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi