Hotline

0942.41.41.41

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar

469,000,000 VND

516,000,000 VND

Máy chiết rót đóng bình tự động 3 trong 1 VAQGF 300 được nhập khẩu bởi công ty CP TMTH Việt An

Mua ngay

Giao hàng miễn phí

Yêu cầu tư vấn

Xây dựng phương án riêng cho bạn

Đặt mua, tư vấn 0942.41.41.41 - 0943.41.41.41 (7:30 - 21:00)

Danh mục: Máy chiết rót , Đóng bình , Máy Chiết Rót Bình Việt An Nhập Khẩu

Mã sản phẩm: VAQGF300

Máy chiết rót đóng bình tự động 3 trong 1 VAQGF 300 với công suất 300 bình 20l trên 1 giờ, phù hợp với các doanh nghiệp kinh doanh sản xuất nước đóng bình tinh khiết.

Sản phẩm được sản xuất theo công nghệ chiết rót hiện đại của Hoa Kỳ. Với 3 công đoạn tự động giúp doanh nghiệp sẽ tiết kiệm được rất nhiều chi phí sản xuất mà năng suất lại tăng gấp nhiều lần so với các loại máy chiết thông thường.

Công ty cổ phần thương mại tổng hợp Việt An là đơn vị tiên phong trong nhập khẩu và phân phối máy chiết rót bình 20 lít chính hãng nhập khẩu từ nước ngoài.

Với độ bền trên 20 năm, tốc độ chiết nhanh, chính xác giúp doanh nghiệp tăng cao năng suất, tăng khả năng cạnh tranh với các đơn vị khác. Máy chiết bình của việt An được cung cấp ra thị trường với mức giá thấp, chính vì vậy mà các loại máy chiết do việt an cung cấp ra thị trường đều nhận được sự tin tưởng của quý khách hàng!

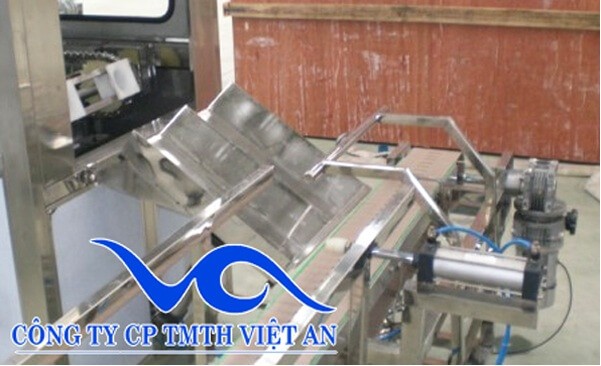

Công đoạn 1. Tráng rửa bình tự động: Bộ phận tráng rửa được thiết kế gồm có xích tải bình, bộ phận giữ bình, motor băng tải, bơm áp đầu inox.

Vỏ bình 20 lít sau khi được rút nắp sẽ được công nhân chuyển tới bộ phận tráng rửa bình tự động. Vỏ bình sẽ được úp ngược vào các đầu tráng rửa và được bộ phận giữ bình giữ cố định. Motor băng tải hoạt động theo chiều cố định để dịch chuyển bình từ công đoạn tráng rửa qua công đoạn chiết rót. Hệ thống bơm áp đầu inox 304 cao cấp có chức năng bơm nước tinh khiết lẫn ozone tiệt khuẩn vào bên trong vỏ bình. Bụi bẩn cũng như các vi khuẩn bám ở trong và ngoài bình sẽ được tiêu diệt sạch sẽ. Toàn bộ quá trình tráng rửa bình diễn ra tự động, công suất lên tới 300 bình 20 lít một giờ.

Công đoạn 2: Chiết rót tự động : Máy chiết bình VAQGF300 được thiết kế gồm 2 đầu chiết rót. Tại đây nước tinh khiết sẽ được đưa vào bình theo định mức đã lập trình qua hệ thống dây dẫn lò xo kết hợp với hệ thống bơm nước đầu inox 304 hoạt động với áp lực từ 0,5-0,6 Mpa.

Công đoạn 3: Đóng nắp bình tự động: Máy chiết rót bình VAQGF300 được trang bị 1 đầu đóng nắp thích hợp với loại bình 20 lít cổ nhỏ không có ren.

Sau khi bình được chiết đầy nước tại công đoạn 2 thì sẽ được hệ thống băng tải đưa tới bộ phận đóng nắp bình tự động. Tại đây với 1 đầu đóng nắp sử dụng áp lực để đóng nắp vào bình. Mỗi giờ máy sẽ đóng được 300 nắp vào bình. Bình sau khi được đóng nắp sẽ có bộ xi lanh thủy lực để đẩy bình nước ra ngoài

Công ty cổ phần TMTH Việt An chúng tôi ngày càng hoàn thiện giá cả cũng như nâng cấp máy móc hiện đại, chế độ bảo hành, bảo trì nhanh chóng để quý khách yên tâm khi đặt hàng ở Công ty Việt An chúng tôi! Hãy liên hệ ngay hôm nay để sở hữu cho mình máy chiết rót đóng bình tự động 3 trong 1 VAQGF 300 chất lượng hoàn hảo.

Máy chiết bình VAQGF300 là một trong những chiếc máy hiện đại mà Việt An cung cấp ra thị trường. Bên cạnh 3 công đoạn tự động được tích hợp trong máy, thì máy còn có khả năng tương thích với các bộ phận tự động khác. Vì vậy mà quý khách hàng có thể mở rộng tối đa tới 12 công đoạn tự động để tạo nên một dây chuyền chiết rót tự động hoàn toàn không cần tới nhân công lao động

Dưới đây là một số công đoạn tự động mà quý khách có thể mua để tích hợp vào với chiếc máy chiết rót đóng bình tự động 3 trong 1 VAQGF300

Với thiết kế gồm 1 đầu rút nắp và hệ thống khung máy được làm bằng chất liệu inox 304 cao cấp. Máy có thể rút được từ 300 đến 600 nắp bình một giờ.

Nguyên lý hoạt động của máy rút nắp bình tự động BG-600: Vỏ bình cần được rút nắp được đưa tới đầu rút nắp của máy. Tại đây dưới áp lực từ 0,6-0,8 Mpa sẽ tác động nên nắp và tách nắp ra khỏi bình. Nắp bình sẽ được tách ra nguyên vẹn không biến dạng nên có thể tái sử dụng.

Thông số kỹ thuật Máy rút nắp bình tự động BG-600

| Model | BG-600 |

| Công suất (nắp/h) | 300-600 |

| Đầu rút | 1 |

| Nguồn điện (kw) | Dùng khí |

| Áp lực (Mpa) | 0.6-0.8 |

| Kích thước (DxRxCmm) | 500x750x1800 |

| Trọng lượng(Kg) | 48 |

| Giá (VNĐ) |

Đây là một chiếc máy ứng dụng công nghệ rửa hiện đại. Với bộ điều khiển thông minh có thể tự vận hành toàn bộ quá trình rửa bình 20 lít. Toàn bộ phần khung máy được làm bằng chất liệu inox 304 cao cấp, bề mặt sáng bóng, dễ dàng vệ sinh và độ bền cao.

Bên trong máy được thiết kế có 3 chổi cọ dùng để cọ 3 bình nước cùng lúc. Chổi cọ có thể xoay 180 để rửa toàn bộ xung quanh bình từ cổ bình, thân bình và đáy bình. Máy có hệ thống bơm nước đầu inox 304 để bơm nước lên rửa bình.

Mỗi giờ máy có thể rửa được từ 300 đến 600 bình 20 lít

Thông số kỹ thuật Máy rửa ngoài bình tự động ST-300

| Model | ST-300 |

| Công suất (bình/h) | 250-300 |

| Đầu rửa | 3 |

| Nguồn điện (kw) | 1.2 |

| Áp lực (Mpa) | 0.7-0.8 |

| Kích thước (DxRxCmm) | 1250x1100x1800 |

| Trọng lượng( Kg) | 230 |

| Giá (VNĐ) |

Với thiết kế gồm 2 đầu tải bình, cùng lúc máy có thể tải được 2 vỏ bình vào chiếc máy chiết rót bình 3 trong 1 VAQGF300 mà không cần tới nhân công lao động. Điều này giúp doanh nghiệp tiết kiệm chi phí sản xuất và tăng hiệu suất lao động.

Chất liệu cấu thành nên chiếc máy tải bình tự động BL-300 này cũng là chất liệu cao cấp inox 304 với độ bền trên 20 năm

Thông số kỹ thuật Máy tải bình tự động BL-300

| Model | BL-300 |

| Công suất (bình/h) | 300 |

| Đầu tải | 2 |

| Nguồn điện (kw) | 0.55 |

| Kích thước (DxRxCmm) | 1050x960x1200 |

| Trọng lượng(Kg) | 40 |

| Giá (VNĐ) |

Với thiết kế thông minh có thể tự động tải nắp bình, cấp nắp cho bộ phận đóng nắp trong chiếc máy chiết rót đóng bình tự động 3 trong 1 VAQGF 300. Máy tải nắp có 1 khay chứa nắp bình, sau khi công nhân đổ nắp bình vào khay chứa nắp của may thì motor băng tải sẽ hoạt động và nắp bình sẽ được tự động đưa lên tới vị trí các đầu đóng nắp. Đặc biệt với thiết kế vô cùng hiện đại, máy có thể tự động cấp nắp khi thiếu và dừng cấp nắp khi đầy nắp. Nắp được cấp vào luôn đúng chiều, không có hiện tượng ngược nắp. Công suất của máy đạt tới 300-1200 nắp mỗi giờ.

Thông số kỹ thuật Máy tải nắp bình tự động CL-1200

| Model | CL-1200 |

| Công suất (nắp/h) | 300-1200 |

| Nguồn điện (kw) | 0.18 |

| Kích thước (DxRxCmm) | 600*600*3000 |

| Trọng lượng(Kg) | 65 |

| Giá (VNĐ) |

Với chiếc máy soi dị vật này thì các cơ sở sản xuất nước uống đóng bình 20 lít có thể kiểm tra xác xuất bình sau khi chiết rót đóng nắp xong có lẫn vật thả lạ không.

Máy soi VADJ-100 được thiết kế gồm có 2 chiếc đèn và bộ khung để bảo vệ đèn soi. Chiếc máy soi dị vật này được đặt ngay sau vị trí của chiếc máy chiết rót đóng bình 3 trong 1 VAQGF300. Hầu như 100% khách hàng sau khi mua chiếc máy chiết rót bình tự động 300 bình 20 lít/h đều mua thêm chiếc máy soi dị vật VADJ-100 này.

Thông số kỹ thuật Máy soi dị vật VADJ-100

| Model | VADJ-100 |

| Nguồn điện (w) | 3 x 20w |

| Kích thước (DxRxCmm) | 600x200x1000 |

| Giá (VNĐ) |

Với thiết kế gồm có 1 nồi hơi, 1 buồng co bình, máy co màng bình bằng hơi nước SK-300 sẽ là một trợ thủ đắc lực cho các cơ sở sản xuất nước uống đóng bình hiện nay.

Nồi hơi có công dụng cấp hơi nước cho buồng co thông qua hệ thống ống dẫn. Những bình nước sau khi được chiết rót đầy nước đóng nắp và được kiểm tra qua máy soi dị vật sẽ được dịch chuyển qua hệ thống băng tải plastic. Công nhân sẽ chụp màng polime vào bình và chuyển tới buồng co màng của máy co màng toàn thân bình. Tại buồng co màng toàn thân bình với sức nóng của hơi nước sẽ làm cho màng co dính chặt vào bình, bình sau đó sẽ được chuyển tới bộ phận in hạn sử dụng và chuyển đến nơi tiêu thụ.

Khi sử dụng chiếc máy co màng bình bằng hơi nước SK-300 do Việt An cung cấp, chung tôi cam kết màng co sẽ không bị nhăn.

Thông số kỹ thuật Máy co màng bình bằng hơi nước SK-300

| Model | SK-300 |

| Công suất (bình/h) | 100-300 |

| Nguồn điện (kw) | 18 |

| Kích thước (DxRxCmm) | 1500x550x800 |

| Giá (VNĐ) |

Công dụng của băng tải chính là dịch chuyển bình tự động, không tốn diện tích, không gian lắp đặt, không cần tới nhân công. Khi quý khách mua máy chiết rót bình tự động VAQGF300 tại Việt An thì quý khách có thể tham khảo mua thêm hệ thống băng tải plastic này. Băng tải plastic có độ bền cao, mà chi phí lại rất hợp lý. Với băng tải plastic CSG-6 này quý khách sẽ tiết kiệm được rất nhiều chi phí thuê nhân công.

Lưu ý: Băng tải plastic CSG-6 chỉ thích hợp cho bình rỗng.

Thông số kỹ thuật Băng tải plastic cho bình rỗng CSG-6

| Model | CSG-6 |

| Nguồn điện (kw) | 0.55 |

| Kích thước (DxRxCmm) | 6000x290 |

| Giá (VNĐ) |

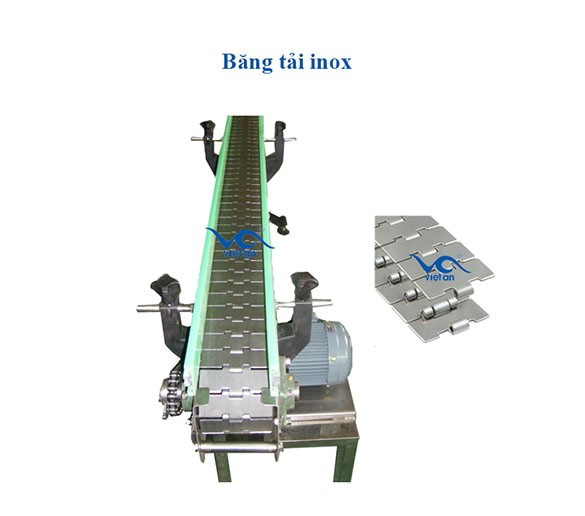

Với kích thước 5000x290 băng tải có thể dịch chuyển bình đầy nước đi mà không cần tới nhân công, không mất diện tích lắp đặt.

Băng tải inox CSSG-5 được thiết kế gồm có hệ thống motor băng tải và băng tải inox 304.

Quý khách có thể kết nối băng tải inox CSSG-5 vào sau chiếc máy chiết rót đóng bình 3 trong 1 VAQGF300 để tạo nên một dây chuyền chiết rót bình tự động, hiện đại hiệu suất cao.

Thông số kỹ thuật Băng tải inox CSSG-5

| Model | CSSG-5 |

| Nguồn điện (kw) | 0.75 |

| Kích thước (DxRxCmm) | 5000x290 |

| Giá (VNĐ) |

Đây là một gợi ý nữa mà Việt An muốn gửi tới quý khách hàng để quý khách có thể tích hợp cùng với chiếc máy chiết rót bình VAQGF300.

Với thiết kế gồm 2 đầu rút nắp, buồng rửa bình có hệ thống chổi cọ cổ bình, thân bình và đáy bình. Chiếc máy sục rửa và rút nắp bình 20 lít VABS-2 sẽ là một sự lựa chọn hoàn hảo nữa cho quý khách hàng

Sau khi quý khách hàng thu mua vỏ bình thì có thể sử dụng chiếc máy VABS-2 để rút nắp và rửa hết bụi bẩn bám vào thân bình.

Thông số kỹ thuật Máy sục rửa, và rút nắp bình 5G VABS-2

| Model | VABS-2 |

| Nguồn điện (kw) | 1.9 |

| Kích thước (DxRxCmm) | 770x1250x1150 |

| Giá (VNĐ) |

Với gần 20 năm xây dựng và phát triển, công ty cổ phần thương mại tổng hợp Việt An tự hào là doanh nghiệp tại Việt Nam về sản xuất, nhập khẩu, phân phối các loại máy chiết rót đóng bình tự động công suất từ 100 bình 20L/h đến 1200 bình 20L/h.

Chúng tôi cam kết tất cả các loại máy mà việt an cung cấp đều đảm bảo tiêu chuẩn chất lượng ISO 9001:2015, chính hãng với mức giá rẻ trên thị trường

Một số cup Việt An đã đạt được

Một số cup Việt An đã đạt được

Xem thêm chi tiết bài viết

A. MÁY CHIẾT RÓT ĐÓNG BÌNH 20L VAQGF300- 3 CÔNG ĐOẠN BẮT BUỘC PHẢI MUA

| Model | VAQGF300 |

| Công suất (bình/h) | 250-300 |

| Đầu chiết | 2 |

| Công suất điện( KW) | 9 |

| Áp lực (Mpa) | 0.5-0.6 |

| Kích thước (DxRxCmm) | 4300x1650x2110 |

| Trọng lượng (Kg) | 780 |

| Đặc tính | Gia nhiệt nước đến 60°C |

| Giá (Triệu đồng) |

B. CÔNG ĐOẠN MUA RIÊNG TÍCH HỢP VÀO MÁY CHIẾT RÓT ĐÓNG BÌNH 20L VAQGF300- 3 IN 1

| Model | Giá( VNĐ) |

| 1. Máy rút nắp tự động BG-600 | |

| 2. Máy rửa ngoài bình tự động ST-300 | |

| 3. Máy tải bình tự động BL-300 | |

| 4. Máy tải nắp bình tự động CL-1200 | |

| 5. Máy soi dị vật VADJ-100 | |

| 6. Máy co màng bình bằng hơi nước SK-300 | |

| 7. Băng tải plastic CSG-6 | |

| 8. Băng tải inox cho bình đã chứa nước CSSG-5 | |

| 9. Máy sục rửa và rút nắp bình 5G VABS-2 |

Đến với Việt An, quý khách sẽ được sở hữu Dây chuyền máy chiết rót VAQGF300 đóng bình tự động, hiện đại với độ bền cao

1 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi

Lê thị Tuyết Hồng

0937857xxx

3 Thích

08:32:05 AM 04/12/2020

VIỆT AN

Quản trị viên

2 Thích

13:17:51 PM 04/12/2020