Hotline

0942.41.41.41

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar Máy làm đá viên 9 tấn và 5 tấn xuất cho anh Văn tại Hải Phòng. Công ty cổ phần thương mại tổng hợp Việt An là một trong những công ty có bề dày kinh nghiệm trong lĩnh vực máy làm đá viên công nghiệp. Được thành lập từ năm 2008, sau hơn 10 năm hoạt động những sản phẩm của Việt An luôn nhận được phản hồi tốt và sự tin tưởng từ khách hàng. Các sản phẩm của Việt An được nhiều công ty, xí nghiệp, bệnh viện và cả trường học,... tin dùng và được hỗ trợ lắp đặt trên toàn quốc. Vì vậy anh Văn đến từ Hải Phòng đã tin tưởng và lựa chọn Việt An làm đơn vị hợp tác thi công lắp đặt 2 chiếc máy làm đá viên IVA9T và IVA5T để phục vụ sản xuất kinh doanh tại địa phương nhằm giải quyết tình trạng đá bẩn nơi đây.

Ngày 7/8/2019 Việt An đã tiến hành xuất máy làm đá viên 9 tấn và 5 tấn cho anh Văn theo hợp đồng 185/2019.

Máy nén mới 100% - được coi như trái tim của hệ thống máy làm đá viên 9 tấn và 5 tấn công nghiệp sử dụng trong hệ thống máy sản xuất đá viên được Việt An đặt riêng cho máy làm đá viên đây là loại máy nén khí. Hiện tại trên thị trường Việt Nam thì chỉ có duy máy sản xuất đá viên của Việt An mới có máy nén mới 100% (tất cả các đơn vị khác đều sử dụng máy nén bãi –tức là máy nén đã qua sử dụng). Máy nén mới của chúng tôi đã được kiểm định chất lượng cực kì khắt khe.

Máy nén mới 100%

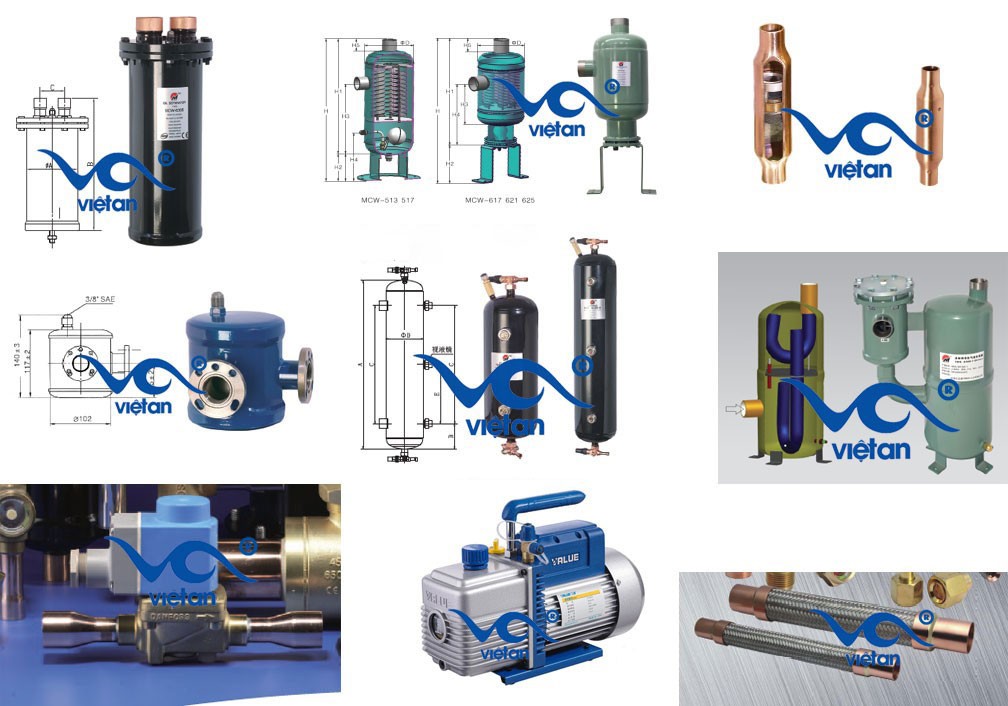

Hệ thống tách dịch khí duy chỉ có ở máy làm đá viên công nghiệp. Do quá trình hoạt động của máy nén có liên quan đến dầu và khí để đảm bảo máy nén không bị nhiễm dịch thì Việt An đã áp dụng hệ thống này. Khi máy nén hoạt động khí được đẩy ra là khí nóng và khí được hút vào là khí lạnh. Vì vậy khí hút vào không được nhiễm dịch lỏng (nước hoặc dầu). Với bộ phận này đường ống của máy làm đá viên sẽ được thiết kế gọn gàng hơn và chu trình hoạt động diễn ra nhanh hơn. Đảm bảo máy nén sẽ đạt được tuổi thọ lâu , tránh hỏng hóc xảy ra.

Hệ thống tách dịch khí

Bình ngưng tụ mới – là một thiết bị không kém phần quan trọng. Toàn bộ quá trình làm việc này có tầm quan trọng lớn trong toàn bộ hoạt động của máy làm đá. Chúng ảnh hưởng mang tính quyết định đến áp suất và nhiệt độ ngưng tụ. Chúng cũng ảnh hưởng trực tiếp đến hiệu quả và độ an toàn hệ thống lạnh của máy làm đá viên.

Bình ngưng tụ

Hệ thống bơm nước cho máy đá Việt An được làm inox 304 được nhập khẩu của Việt An. Hiện tại chỉ có máy làm đá viên công nghiệp của Việt An mới sử dụng bơm iNox 304 vì đây là sản phẩm được chúng tôi đặt riêng cho máy làm đá viên.

Bơm iNox

Hệ thống điện tự động, rất dễ dùng – kể cả đối với những khách hàng chưa từng có kinh nghiệm về điện lạnh, chỉ cần được hỗ trợ hướng dẫn sẽ vận hành 1 cách trơn chu.

Hệ thống điện

Hệ thống van mới 100% nhập khẩu từ các nước nổi tiếng, không phải dòng van gia công.

Vì đây là dòng sản phẩm có thiết kế bằng INOX 304, nên anh Văn có thể hoàn toàn yên tâm về thời gian sử dụng – trung bình 1 chiếc máy này có thể sử dụng tốt với thời gian lên đến 20 năm.

Các linh kiện ở máy làm đá viên 9 tấn và 5 tấn

Mức giá của máy làm đá viên công nghiệp cực kỳ ưu đãi – quý khách có thể tham khảo sản phẩm máy đá viên của Việt An so với các dòng sản phẩm khác có cùng công suất đang bán trên thị trường để có sự lựa chọn tốt .

Không chỉ anh Văn mà rất nhiều khách hàng khi đến với Việt An đều quan tâm đến quy trình sản xuất của 1 chiếc máy làm đá viên công nghiệp, hiểu rõ được quy trình tạo đá sẽ giúp bạn vận hành máy một cách dễ dàng hơn bao giờ hết.

Nước qua quá trình lọc (anh Văn nên chọn nguồn nước theo quy định như nước giếng khoan, nước ngầm… ). Bơm nước vào bình chứa, nằm bên dưới cối đá.

Dùng hệ thống máy bơm nước được cấu tạo từ iNox, để chuyển nước từ hồ chứa nước dưới lên hồ chứa nước trên, kế đến là cho nước đi qua hệ thống ngưng tụ hay thiết bị ngưng tụ với nhiệm vụ ngưng tụ gas quá nhiệt sau máy nén thành môi chất lạnh trạng thái lỏng.

Dẫn môi chất này vào các ống đá bên trong cối đá (nằm bên dưới hồ chứa nước phía trên và bình ngưng).

Máy nén sẽ bắt đầu hoạt động, kết hợp với môi chất lạnh R22 trong máy làm đá viên - để truyền hơi lạnh vào bên trong ống đá (nhiệt độ lúc này vào khoảng âm 20 độ C), hơi nước trong ống sẽ dần dần kết tinh chuyển thành dạng đá và bám vào bên trong thành ống.

Sau khoảng thời gian 40 phút đến 45 phút, đá viên đã được hình thành, hệ thống máy nén sẽ đảo chiều để bơm khí nóng vào cối đá, giúp tách 1 lớp đá mỏng để đá rơi khỏi ống.

Sau khi đá rời ống, sẽ được hệ thống dao cắt bên dưới cối đá, cắt đá thành từng viên với kích thước chỉnh sẵn.

Thời gian tối thiểu Việt An thực hiện bảo hành các dòng máy làm đá này là 1 năm. Trong thời gian này khi máy gặp lỗi kỹ thuật, anh Văn sẽ được phía công ty Việt An sửa chữa miễn phí.

Mức giá máy làm đá viên với linh kiện mới 100% luôn tốt trên thị trường. Tặng nguyên gói vận chuyển miễn phí đến Hải Phòng cho anh Nam cũng như mọi đối tượng khách hàng trên toàn quốc.

Nhiều phần quà hấp dẫn, ữu đãi lớn cho anh Nam.Đặc biệt tặng kèm hệ thống đóng gói cho anh Văn. Giảm giá đặc biệt khi anh mua những sản phẩm tiếp theo của Việt An.

Cảm ơn anh Văn đã tin tưởng lựa chọn Việt An. Để hữu cho mình sản phẩm máy làm đá viên 9 tấn và 5 tấn chất lượng tuyệt như mọi khách hàng của chúng tôi, khách hàng có thể ghé thăm các chi nhánh của chúng tôi tại Hà Nội, Đà Nẵng, Buôn Ma Thuột, Hồ Chí Minh hoặc gọi trực tiếp hotline: 0943 41 41 41. Để được hỗ trợ và tư vấn tốt . Việt An xin chân thành cảm ơn!

Hỏi đáp & đánh giá Máy làm đá viên 9 tấn và 5 tấn xuất cho anh Văn tại Hải Phòng

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi