Hotline

0942.41.41.41

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar Dây chuyền sản xuất chai nhựa mới 2019 Chai nhựa tuy chỉ là vật đựng nhưng lại chiếm tới 30 – 40% giá thành chai nước. Ngày nay, việc tự thổi chai để tiết kiệm chi phí, thời gian mua chai đã là nhu cầu thiết yếu của các nhà sản xuất nước uống đóng chai. Tự thổi vỏ chai còn giúp nhà sản xuất chủ động về mẫu mã, một phần quan trọng đó là tạo nên giá trị thương hiệu riêng cho doanh nghiệp.

Dây chuyền sản xuất chai nhựa mới 2019

Xã hội phát triển, vỏ chai hộp nhựa cũng dần vượt ra khỏi chức năng truyền thống. Không chỉ dùng để chứa đựng sản phẩm, chai nhựa giờ đây còn là phương tiện kết nối, giúp đưa sản phẩm đến gần người tiêu dùng hơn. Một sản phẩm mà chúng ta bắt gặp hàng ngày được chứa trong chai nhựa chính là nước uống đóng chai. Được biết đến nhiều với tên gọi chai nhựa, chai PET nhưng ít ai nắm rõ quy trình sản xuất chai nhựa này.

Hãy cùng Việt An tìm hiểu rõ hơn về cách thức chai nhựa được sản xuất và đến tay người tiêu dùng. Chúng tôi chính là đơn vị cung cấp máy thổi chai, dây chuyền sản xuất chai nhựa mới 2019 uy tín tại Việt Nam.

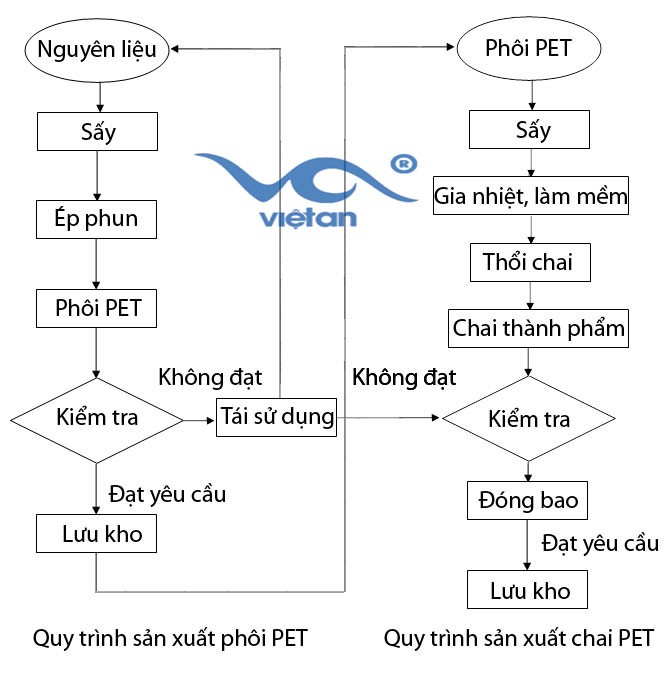

Việc sản xuất chai nhựa thông thường chia thành 2 giai đoạn đoạn chính:

Quy trình sản xuất chai nhựa phổ biến

Gia đoạn 1: Sản xuất phôi PET

Giai đoạn này gồm 2 giai đoạn nhỏ hơn là nhựa hóa trong xilanh nguyên liệu, sau đó tạo hình bằng khuôn.

Vì chai nhựa đựng trực tiếp thực phẩm nên nguyên liệu sản xuất phải là nhựa nguyên , không nhiễm các kim loại nặng trong nhựa phế, đặc biệt đối với nước đóng chai, quá trình này càng phải nghiêm ngặt. Vì nhựa nguyên nên chất lượng sản phẩm cao, giá thành cao, đối với những loại chai rẻ tiền, công ty sản xuất đã pha nhựa tái chế vào, khi kinh doanh bạn cần lưu ý điều này, nó không những ảnh hưởng tới sức khỏe người tiêu dùng mà công việc kinh doanh của bạn cũng theo đó mà đi.

Hạt nhựa được nung chảy ở nhiệt độ 180 độ C khoảng 4 giờ, nhựa chuyển từ thể rắn sang thể lỏng sẽ được bơm vào khuôn tạo sẵn, sau đó phôi bơm vào được làm nguội và đưa vào hệ thống làm lạnh.

Chu kì ép phôi chỉ diễn ra khoảng vài phút đổ lại, các phôi được tạo hình sẽ được chuyển ra thùng chứa để kĩ thuật kiểm tra bọt khí, những sản phẩm đạt tiêu chuẩn được làm nguội ngoài không khí một thời gian, đóng bao và chuyển đến khâu thổi chai.

Giai đoạn 2: Thổi chai nhưạ

Quá trình thổi gồm 2 giai đoạn: gia nhiệt làm mềm phôi, sau đó thổi chai trong khuôn.

Phôi được chuyển vào hệ thống sấy để làm mềm dẻo hơn, tiếp theo được gắn lên ngàm kẹp, khuôn lúc này được đóng kín, thanh đẩy trong máy kéo phôi xuống dưới đáy khuôn. Lúc này đồng thời, áp lực trong lòng khuôn được làm tăng lên bằng cách bơm thêm khí nén và thổi, phôi sẽ bị đẩy ra ngoài, hình dạng được định hình như khuôn, đến khi phôi ra hoàn toàn, định hình y đúc như khuôn thì sẽ được làm nguội bằng nước lạnh.

Kết thúc quá trình, thanh đẩy kéo lên, những phần còn lại của khuồn được tách ra và sản phẩm được đẩy ra ngoài, sau đó chai sẽ được kiểm tra lần cuối, rồi mới lưu kho và chuyển vào khâu chiết rót.

Giai đoạn 3: Chiết rót

Đầu tiên, các chai được đưa lên hệ thống băng tải và đi qua hệ thống súc rửa để làm sạch bụi bẩn.

Sau khi được rửa sạch, các chai được băng tải đưa đến hệ thống máy chiết rót, vào vị trí rót để đảm bảo có thể bố trí các thanh kẹp giữ chai. Tại đây, chất lỏng được chiết vào chai theo các phương pháp khác nhau, chiết đẳng áp, chiết đẳng tích, chiết định lượng… Khi chiết xong, chai được băng tải vận chuyển đến vị trí đóng nút hoặc đóng nắp.

Sau khi đóng nắp xong, là khâu dán nhãn, đây có thể coi là khâu đơn giản trong hệ thống đóng chai. Khâu cuối cùng là khâu kiểm tra và đóng gói sản phẩm. Khâu kiểm tra bao gồm 1 loạt các cảm biến để kiểm tra chất lượng sản phẩm (đủ định mức, đóng nút, dán nhãn đạt yêu cầu…) sau khi kiểm tra chai không đạt tiêu chuẩn sẽ bị loại ra. Các chai đạt tiêu chuấn sẽ qua khâu đóng gói.

Trên đây là dây chuyền sản xuất phôi chai nhựa chất lượng. Bất kỳ sự cố nào xảy ra cũng có thể làm ảnh hưởng đến chất lượng phôi cũng như chất lượng nhựa nói chung. Vậy mua dây chuyền sản xuất chai nhựa ở đâu uy tín ? hãy đến với công ty Việt An để được cung cấp sản phẩm với mức giá ưu đãi và chất lượng .

Công ty cổ phần thương mại tổng hợp Việt An được cổ phần hóa từ tháng 8/2009. Là doanh nghiệp hàng đầu và nhập khẩu, phân phối máy chiết rót, máy thổi chai, dây chuyền lọc nước và sản xuất máy làm đá viên.

Trong gần 20 năm qua, Việt An không ngừng nỗ lực hoàn thiện nâng cao chất lượng sản phẩm, cải tiến kỹ thuật. Luôn xây dựng thương hiệu bằng chất lượng và niềm tin của khách hàng. Chính vì vậy mà Việt An đã nhận được rất nhiều chứng nhận, giải thưởng cao quý.

Huy chương vàng hàng Việt Nam chất lượng cao năm 2009

Cúp Sen vàng hàng Việt Nam chất lượng cao năm 2009

Huy chương vàng thương hiệu dẫn đầu Việt Nam năm 2015

Chứng nhận thương hiệu Việt An đạt chứng chỉ ISO 9001:2015

Thương hiệu xuất sắc 3 miền 2017

Cùng vô số những giải thưởng cao quý khác.

Cam kết dây chuyền sản xuất chai nhựa tại Việt An hiện đại thị trường, ứng dụng công nghệ sản xuất hiện đại của Hoa Kì giúp nâng cao hiệu suất, tiết kiệm chi phí thuê nhân công. Toàn bộ quá trình sản xuất, lắp ráp đều đảm bảo tiêu chuẩn ISO 9001:2015.

Dây chuyền sản xuất chai nhựa mới 2019 có lợi ích rất nhiều cho doanh nghiệp, giúp các doanh nghiệp đạt năng suất cao, vừa tiết kiệm số lượng nhân công vừa tiết kiệm thời gian và chi phí. Để mua các hệ thống máy thổi phôi, máy thổi chai pet, máy chiết rót, quý khách có thể liên hệ qua hotline: 0942 41 41 41 để được tư vấn và hỗ trợ!

Hỏi đáp & đánh giá Dây chuyền sản xuất chai nhựa mới

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi